Quality Assurance

Approach and Policy

The SMM Group has established a business model centered on collaboration among its three core businesses: Mineral Resources, Smelting and Refining, and Materials Businesses. Through this integrated business model, we strive to continuously refine our products, respond to changing customer needs, and provide quality that ensures customer satisfaction.

To ensure the delivery of high-quality products that satisfies customers, the President has established a Company-Wide Quality Policy and sets annual SMM Quality Objectives. In line with these standards, each business division sets and executes division-specific quality objectives, and the entire Group carries out quality assurance activities under the same policy.

Quality Assurance Management Framework

Under the ultimate oversight of the president, an executive officer responsible for the Quality Assurance Department has been appointed to oversee and advance the Group’s quality assurance initiatives. While each business division develops and maintains its own quality assurance framework, the Quality Assurance Department exercises company-wide oversight, serving as a cross-functional organization responsible for quality management throughout the Group.

Furthermore, the Quality Assurance Working Group, a subordinate body of the Sustainability Committee, deliberates on key measures for promoting quality assurance activities. It also shares each division’s progress toward targets and quality control status, including reductions in customer complaints, to support ongoing improvements to the Quality Management System (QMS).

The quality assurance managers from the various business divisions and business sites, together with members of the head office’s Quality Assurance Department also hold an annual quality meeting to share the quality management status of each business site and discuss quality issues common across the entire Group.

■ Management Framework Chart

Company-Wide Quality Objectives and Results

Company-Wide Quality Policy

“Provide high quality to satisfy our customers through continual improvements of quality assurance and control systems.”

- Pursue high quality that is ahead of its time

- Comply with relevant laws and regulations, and strive to create products that prioritize safety and environmental considerations

FY2024 Results

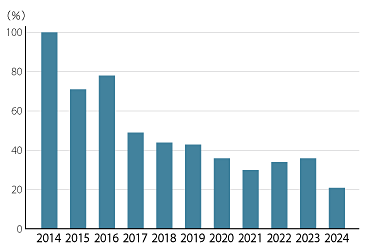

The chart below shows the trend in quality complaints across our entire group, with FY2014 set as the reference value of 100. In FY2024, the number of quality complaints decreased to approximately one-fifth of the level in FY2014.

While the total number of quality complaints decreased substantially in FY2024, primarily as a result of the business transfer of an affiliated company, some divisions experienced issues attributable to human error. To address this, we will strengthen our risk analysis, implement countermeasures to eliminate root causes, and continue promoting quality improvement initiatives across all business divisions and sites.

■ Changes in Quality Complaints (ratio with FY2014 set as the reference value of 100)1

- 1The FY2024 figure excludes the number of claims from Sumitomo Metal Mining Siporex Co., Ltd. due to the transfer of business operations.

FY2025 Company-Wide Quality Objectives

“Pursue QMS improvements to establish a corporate structure that earns customer trust”

- Zero major quality complaints.

Proactively prevent any quality issues that could compromise the stability of our business base - Zero occurrences of quality misconduct

- Meet the goals for complaints in each business division

Quality Improvement Initiatives

Issues and Initiatives for Improvement

Customer-trusted high quality is only possible when every employee is united in their purpose and strategic direction and actively participating in the activities required to meet the goals. To this end, we identify our challenges based on the information gathered through internal and external communication, set appropriate objectives, and actively involve all employees in improvement initiatives based on the “SMM Quality Standard,” which outlines the ideal framework of our QMS.

Improving Effectiveness of the Quality Management System (QMS)

The SMM Group has established and implemented a company-wide QMS across all business divisions and sites. To ensure the effective functioning of our QMS, we carry out improvement activities based on the SMM Quality Standards . Each fiscal year, every business site sets its own goals for achieving the SMM Quality Standards and carries out improvement activities accordingly. These activities are evaluated and reviewed through internal quality audits and audits conducted by the Quality Assurance Department. At the end of the fiscal year, a self-assessment is performed to determine whether the targeted quality levels have been achieved. Based on these results, new objectives are set for the following fiscal year, and the PDCA improvement cycle is implemented to continuously enhance the effectiveness of the QMS at each business site.

The SMM Quality Standard classifies requirements into eight chapters. By incorporating past issues into the checklists, it identifies each site's strengths and weaknesses, focusing improvement efforts on those weaknesses.

SMM quality standards undergo annual revisions, and by continuously improving the ideal state of the QMS our Group seeks, we will strive to provide high-quality products that satisfy our customers.

■ Overview of QMS and Applicable Items in SMM Quality Standards

Strengthening of Our Internal Quality Audits

We carry out activities aimed at performing internal quality audits using the SMM Quality Standard as our reference. These audits identify systemic issues that may be hidden beneath surface-level problems from an objective, third-party perspective and communicate them to top management. We provide training to develop internal quality auditors across our business sites in Japan and have trained approximately 670 auditors between FY2019 and FY2024. During actual audits, internal quality auditors are present to verify the effectiveness of the audits conducted by their peers, thereby enabling the PDCA cycle for the development and training of internal quality auditors.

To guard against quality misconduct, such as the falsification of inspection and test data, we are offering company-wide quality fraud prevention training using e-learning. Additionally, as a deterrent mechanism, we carry out internal quality audits to verify the reliability of inspection and test data used to guarantee product quality. We are promoting company-wide efforts to automate the transfer of inspection and test data to minimize human intervention, and to strengthen management countermeasures where automation is difficult.

Expansion of Group-Wide Education on Quality

We provide education for all employees, from new employees to managers and supervisors, in order to equip them with the knowledge and management skills required for quality. We launched the e-learning program “SMM Hinkaku1” for all employees in fiscal 2019 to broaden their knowledge and enhance their awareness of quality. Approximately 5,900 employees have completed the training. We will utilize “SMM Hinkaku” for training new employees and transfers henceforth.

As a shortage of human resources capable of assuming quality management responsibilities is anticipated in the future, we are conducting training to cultivate company-wide quality managers. Through four practical training sessions each year, we aim to implement the SMM Quality Standards across business divisions and strengthen the effectiveness of the QMS. After completing the course, the participants will identify issues to be addressed for their own business sites and aim to use the knowledge and skills acquired during the training to resolve these issues. The Quality Assurance Department also follows up on the progress of these initiatives. A total of 20 employees completed the training in FY2024.

- 1Trainees acquire the fundamental knowledge and quality awareness required in manufacturing, and their proficiency is evaluated through a test

Products and Services Information Disclosure

GRI 416-1

The products handled by our Group are primarily provided as materials or components for manufacturing our customers' products. Information essential for the safe and environmentally responsible handling of our Group’s products, as well as for their proper delivery to customers, is communicated based on past and current data, our Group’s proprietary expertise, and relevant studies. This information is provided through contract specifications, technical meetings, product inspection reports, Safety Data Sheets (SDS)1, and other channels. SMM products supplied to customers are delivered following careful product design that prioritizes safety and environmental compliance, and are subject to rigorous testing and manufacturing inspections2. The information used for these purposes is reviewed through the QMS, taking into account the latest technology, regulations, and customer requirements, to ensure it remains accurate and appropriate at all times.

- 1Safety Data Sheet (SDS): A document providing information on a chemical product, including its chemical composition, product name, supplier details, associated hazards, safety precautions, and emergency response procedures

- 2Life Cycle Assessments (LCA) for copper, nickel, and zinc through associations related to each metal

Communication with Customers

Customer satisfaction surveys are proactively conducted by each business division and site. The results of the survey are provided as feedback to the sales and development divisions. To improve customer satisfaction, we are continuously refining our methods for measuring and evaluating customer satisfaction. Through accurate and comprehensive communication with customers, we are able to pinpoint issues and implement effective corrective measures. Furthermore, by engaging in quality improvement activities, our Group promotes resource conservation and energy efficiency through improved product yield.

Information on SMM Products Requiring Disclosure by Labeling and Applicable Products/Services

GRI 417-1 / 417-2

Necessary information regarding our products and services, including labeling, is disclosed as shown in the table below.

| Information requiring disclosure | Applicable products/services |

|---|---|

| Whether the components of products and services are outsourced | All materials subject to regulation and control by law Not applicable to our main products (raw materials and internally processed materials) |

| Whether the contents contain any material that may significantly impact the environment or society | All materials subject to regulation and control by law |

| Information on the safe use of products and services | All materials subject to regulation and control by law |

| Whether disposal of the product may significantly impact the environment or society | All materials subject to regulation and control by law |

Method of Providing Information on Specifications

We communicate product information to our customers by clearly specifying the required details in the delivery specifications.

Method of Providing Information on Chemical Substances

Our Group ensures compliance with chemical substance regulations and promotes safe handling by providing customers with comprehensive information on product contents through SDSs and supporting documents.

Other Initiatives

Our Group also operates businesses aimed at general consumers, including the sale of various lubricants. Information about these products and services is provided in compliance with applicable laws, including labeling, advertising, and explanations to ensure proper understanding.

Responding when Product Quality Issues Occur

Should a quality issue arise with any of our Group’s products or services, appropriate measures are determined in accordance with the “Quality Assurance Regulations.” The business divisions and business sites will immediately verify the facts, report the results of the root cause analysis to the customer, and implement corrective actions and preventive measures to avoid recurrence.

Should a major quality issue arise, the business division immediately notifies management and the General Manager of the Quality Assurance Department, who in order to resolve quality issues immediately, will check the progress of necessary response measures, and confirm the effectiveness of corrective actions and measures to prevent recurrence.