Smelting & Refining Business

With the smelting and refining technology that we have estabilished over more than 430 years since our founding, we contribute to society through the stable supply of high-quality metal materials from low-grade ore that it was once impossible to recover metal from. We also support to build a sustainable circular economy by providing batteries recycling process.

Strengths of Sumitomo Metal Mining’s Smelting & Refining Business

Strength 1

World-class cost competitiveness and

technological capabilities

The origin of Sumitomo Metal Mining’s technology is a smelting technique known as "Nanban-buki.”In the 430 years since its founding, Sumitomo Metal Mining has perfected its smelting and refining technology and been at the forefront of the industry. We were the first in the world to successfully commercialize HPAL technology for the recovery of nickel intermediates from low-grade nickel oxide ore, and we produce highly pure nickel by combining this with a high-efficiency production method called MCLE. In terms of copper smelting and refining, the Toyo Smelter & Refinery has a production capacity of 450,000 tonnes on a single line, and boasts global top-class cost competitiveness.

Strength 2

Effective utilization of

finite mineral resources

This HPAL technology enables the recovery of the metals such as nickel and cobalt from low-grade nickel oxide ores that had hitherto not been in the scope of smelting and refining. Furthermore, Sumitomo Metal Mining was the first in Japan to achieve “battery-to-battery” reuse of resources whereby copper and nickel are recovered from the used lithium ion secondary batteries and then given new life as battery materials. In this way, we are contributing toward the construction of a sustainable circular economy.

Strength 3

Co-existence and co-prosperity with local communities,

and responsible environment management

Since long ago, Sumitomo Metal Mining has always worked to overcome the impact of its operations on the surrounding environment, and its successes include resolving the problem of smoke pollution in the Meiji Period. In terms of our operations at Coral Bay in the Philippines, in 2019 we were recognized by being selected as the winner of the ASEAN Mineral Awards for striving to operate in a socially responsible manner by contributing to the surrounding area through building infrastructure for local communities, increasing employment, and sourcing materials locally alongside other such actions as well as operating with the minimum environmental impact, and restoring the ecosystem by rehabilitation of tailings dams.

Smelting & Refining Business in Visual Media

Sumitomo Metal Mining in pictures. Learn about SMM's businesses and products in pictures.

-

Bird's eye view of the Taganito HPAL Nickel Corporation plant

Main smelting and refining bases

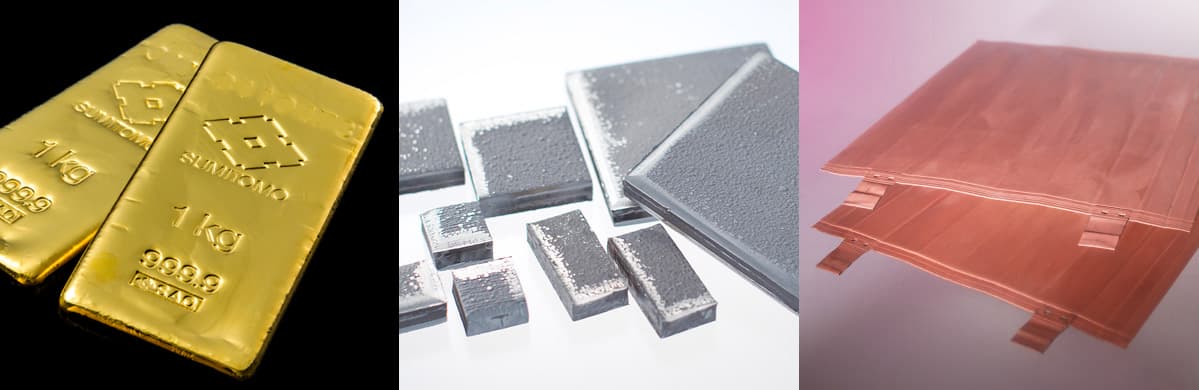

Metal Products

Through the application of the cutting-edge smelting and refining technology, it creates from minerals the metals that support society.