Photo Gallery

Taganito HPAL Nickel Corporation plant(Philippines)

Smelting & Refining BusinessNickelTaganito / Coral Bay

This is our second HPAL plant in the Philippines. The SMM Group produces mixed nickel-cobalt sulfide from low-grade ore using the HPAL technology that it successfully commercialized before anyone else in the world, and ships it to its Niihama Nickel Refinery and Harima Refinery as intermediates materials for nickel product such as electrolytic nickel and nickel sulfate. Production started in 2013.

Kunitomi Mine Smokestack

Smelting & Refining BusinessThe History of Sumitomo Metal Mining

The smokestack at the Kunitomi Mine in Kyowa-cho in Hokkaido’s Iwanai District was completed in 1944 to expel the exhaust from the copper smelting and refining work at the Kunitomi Mine. Having completely fulfilled this role in 2002, it was demolished in August 2013. The great smokestack that could be seen from a long way away witnessed the ebb and flow of post-war business and was close to the hearts of the residents of Kyowa-cho as a landmark of the town.

Analysis to identify the value of material

Materials Business

Accurate analysis is essential when it comes to the manufacturing of cutting-edge, advanced materials. Sumitomo Metal Mining performs precise component analysis and quantitative analysis.

Toyo Smelter & Refinery

Smelting & Refining BusinessCopperToyo Smelter & Refinery

This is a copper refining base located in the city of Saijo in Japan’s Ehime Prefecture. The flames of its flash furnace carry on the spirit of Sumitomo that originates in the kiln of the Besshi Copper Mine. After half a century since operations started at the plant in 1971, it has grown to become one of SMM’s core smelters and now boasts global top class production capacity and cost competitiveness. As well as electrolytic copper and copper sulfate, it also produces gold ingots, gold shots, and silver shots among other things.

Remains of the Besshi Copper Mine with greenery restored through reforestation

Besshi Copper MineThe History of Sumitomo Metal Mining

After an exposed copper vein was discovered in Iyo Province (currently southeast of Niihama City in Ehime Prefecture) in 1690, felling of the mountain forests continued over many years, and trees disappeared from the area. And so in 1894, reforestation work got underway. As a result of the reforestation, which saw two million trees planted a year at its peak, the mountain forest has now recovered to a state of abundant greenery and nurtures a diverse ecosystem.

A gold ingot produced at the Toyo Smelter & Refinery

Smelting & Refining BusinessGoldToyo Smelter & RefineryMineral Resources BusinessHishikari Mine

Gold mineral ore is smelted and refined at the Toyo Smelter & Refinery into gold with a purity of 99.99% and cast into ingots of a specific weight. The ingots are complete after they have been engraved with a mark, number, and purity.

Oxide ore mined at an overseas copper mine

Mineral Resources BusinessCopper

The purity of the mined ore is increased through mineral processing before it moves on to the smelting and refining process.

Cerro Verde copper mine (Peru)

Mineral Resources BusinessCopperCerro Verde

Located in Peru, SMM acquired an interest in this copper mine in 2005. Cerro Verde is one of the global top class mines alongside the Morenci copper mine (USA) .

The mined ore of copper grade less than 1% becomes copper concentrate through mineral processing its copper content raised to 23%. Copper concentrates are shipped to Toyo Smelter & Refinery with approximately two-month sea journey and become electric copper of purity more than 99.99% after smelting and refining process.

Dump trucks at the Cerro Verde copper mine(Peru)

Mineral Resources BusinessCopperCerro Verde

Large dump trucks transport the mined ore.

Dump trucks at the Cerro Verde copper mine(Peru)

Mineral Resources BusinessCopperCerro Verde

Large dump trucks transport the mined ore.

Mining at the Cerro Verde copper mine(Peru)

Mineral Resources BusinessCopperCerro Verde

Cerro Verde is a open-pit copper mine. Large heavy machinery is used to dig down from the surface.

Cerro Verde copper mine(Peru)

Mineral Resources BusinessCopperCerro Verde

Cerro Verde is a open-pit copper mine. Large heavy machineries is used to dig down from the surface.

Taganito HPAL Nickel Corporation(Philippines)

Smelting & Refining BusinessNickelTaganito / Coral Bay

This is a night view of the Taganito HPAL Nickel Corporation in the Philippines.

A sculpture received to commemorate the acquisition of additional interest in the Morenci copper mine(USA)

Mineral Resources BusinessCopperMorenciThe History of Sumitomo Metal Mining

In 2016, 30 years since the original acquisition of interest, Freeport-McMoRan and SMM concluded the acquisition of additional interest in Morenci copper mine. Over the course of many years, SMM has developed a deep relationship of trust with its partners and the local community.

Copper mineral ore that is mined around the world

Mineral Resources BusinessCopper

The Sumitomo Metal Mining Group leverages the partnerships with global resource companies it has built up over the course of many years to participate in the management of leading copper mines around the world including the Morenci copper mine in the USA and the Cerro Verde copper mine in Peru.

Candelaria copper mine (Chile)

Mineral Resources BusinessCopperCandelaria

The Candelaria copper mine is located in Region III (Atacama Region) of Chile, a major country in the field of mineral resources. SMM acquired an interest in this mine in 1992.

The Ome District Division: supporting the global electronics industry

Materials BusinessOme District Div.

The Ome District Div. in Tokyo’s Ome City is a main production and supply base of Sumitomo Metal Mining Group’s advanced materials. It carries on the serious approach to manufacturing that the group has always had, and works continuously to ensure a stable supply of high-quality products.

AuSn frames: for the trend towards IoT and 5G

Materials Business

AuSn preforms are a gold-tin alloy solder material . Electronic components are increasing due to the progress of IoT and 5G telecommunication. The need for highly advanced materials is increasing.

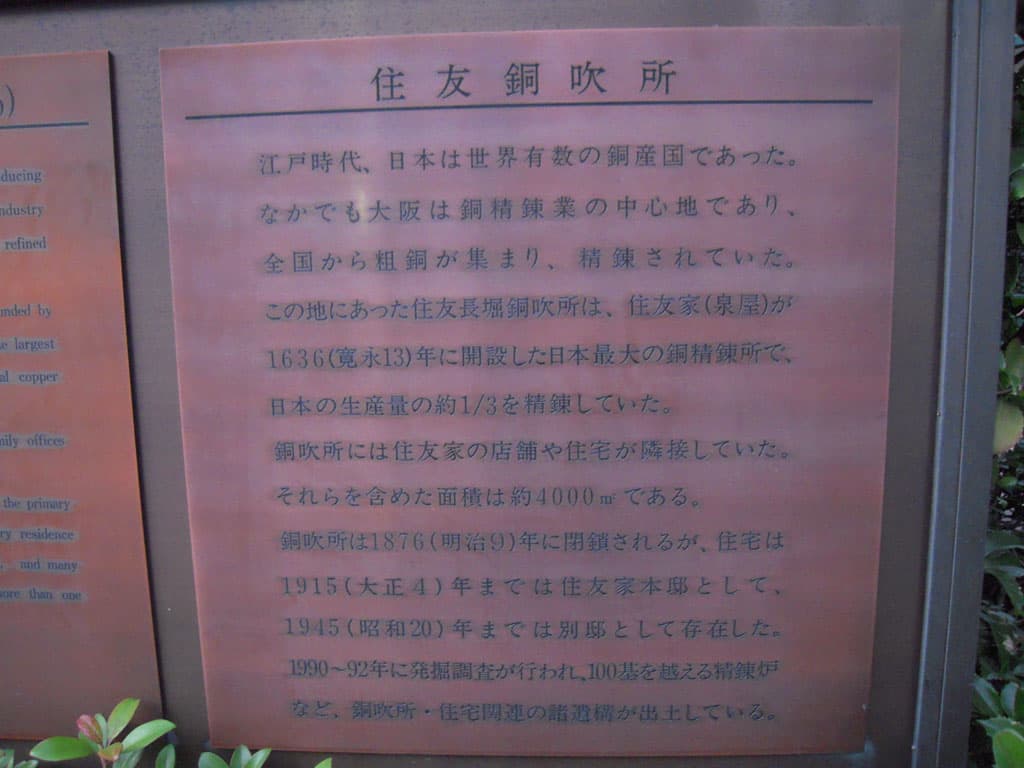

The remains of the Sumitomo copper blowing factory speak of past prosperity

Smelting & Refining BusinessThe History of Sumitomo Metal Mining

In Shimanouchi 1-chome in Osaka’s Chuo Ward, you can find the monument to an old copper blowing factory (refinery) opened by the house of Sumitomo (Izumiya) around 1640. There are many rivers in the surrounding area, and many copper blowing factories were built here given its convenient location in terms of transportation. Japan was one of the leading copper-producing countries in the world at that time, and copper mineral ore from around the country was gathered here before being smelted and refined and shipped overseas. It is said that the Sumitomo copper blowing factory once refined a third of the copper produced in Japan.

The remains of the Sumitomo copper blowing factory speak of past prosperity

Smelting & Refining BusinessThe History of Sumitomo Metal Mining

In Shimanouchi 1-chome in Osaka’s Chuo Ward, you can find the monument to an old copper blowing factory (refinery) opened by the house of Sumitomo (Izumiya) around 1640. There are many rivers in the surrounding area, and many copper blowing factories were built here given its convenient location in terms of transportation. Japan was one of the leading copper-producing countries in the world at that time, and copper mineral ore from around the country was gathered here before being smelted and refined and shipped overseas. It is said that the Sumitomo copper blowing factory once refined a third of the copper produced in Japan.

Electrolytic copper supports today’s society

Smelting & Refining BusinessCopperProducts

Electrolytic copper is one of the Sumitomo Metal Mining Group’s main products. It has a wide range of uses that include everything from electric cables to electronics and is one of the base metals that support today’s society.

Nickel sulfate: used in a wide range of fields

Smelting & Refining BusinessNickelNiihama Nickel RefineryProductsHarima Refinery

As well as being widely used for nickel plating, nickel sulfate produced by Sumitomo Metal Mining is also used for aluminum coloring, catalysts, battery materials, and other such fields.

Underground work at the Hishikari Mine

Mineral Resources BusinessGoldHishikari Mine

After crushing ore by blasting (with explosives), it is removed to the surface.

Heavy machinery traffic in drifts

Mineral Resources BusinessGoldHishikari Mine

The drifts of the Hishikari Mine are a network of passageways that are wide enough to enable heavy machinery to travel freely.

Taganito HPAL Nickel Corporation(Philippines)

Smelting & Refining BusinessNickelTaganito / Coral Bay

This is a night view of the Taganito HPAL Nickel Corporation in the Philippines.

The Cerro Verde copper mine(Peru) is in a desert

Mineral Resources BusinessCopperCerro Verde

The location of the Cerro Verde copper mine is a desert area that receives only 40mm of rainfall on average per year. Only plants that are specially adapted to such a harsh environment can survive here.

Electrolytic nickel produced at the Niihama Nickel Refinery

Smelting & Refining BusinessNickelNiihama Nickel RefineryProducts

Electrolytic nickel produced by Sumitomo Metal Mining has a nickel purity of 99.99% This is an absolutely essential metal for cutting-edge technology in Japan and is used in things such as electronic industry materials and specialized steels. SMM is the only company that produces electrolytic nickel in Japan.

Toyo Smelter & Refinery converter process

Smelting & Refining BusinessCopperToyo Smelter & Refinery

In order to make blister copper with a purity of around 98% from copper concentrate containing about 25-30% copper, it is first concentrated to 60-65% in the flash furnace. It is then sent to the converter to increase its purity. There, blister copper with a purity of 98% is extracted, and the oxygen density is adjusted in a refining furnace.

Electrolytic copper produced at the Toyo Smelter & Refinery

Smelting & Refining BusinessCopperToyo Smelter & Refinery

The copper that is extracted from the refining furnace becomes electrolytic copper with a purity of 99.99% through the electrolysis process.

Toyo Smelter & Refinery gold casting process

Smelting & Refining BusinessCopperToyo Smelter & Refinery

As well as copper, the Toyo Smelter & Refinery casts gold ingots of a variety of sizes and also produces gold shots. After being placed in a flash furnace, gold ore produced at the Hishikari Mine is processed at a precious metals plant and is extracted as gold with a purity of 99.99%. The trace amounts of gold found in the copper concentrate are also completely recovered.

Copper casting at the Toyo Smelter & Refinery

Smelting & Refining BusinessCopperToyo Smelter & Refinery

The copper that is extracted from the refining furnace is cast in a mold and forms a refined anode. A refined anode is an anode plate for producing electrolytic copper with a purity of 99.99% through electrolysis and weighs approximately 400kg.

Copper casting at the Toyo Smelter & Refinery

Smelting & Refining BusinessCopperToyo Smelter & Refinery

The copper that is extracted from the refining furnace is cast in a mold and forms a refined anode. A refined anode is an anode plate for producing electrolytic copper with a purity of 99.99% through electrolysis and weighs approximately 400kg.

Nickel hydroxide: essential for hybrid vehicles

Materials BusinessNickelProducts

Nickel hydroxide is used mainly in hybrid vehicles as a cathode active material for nickel metal hydride batteries. Having the integrated production from the nickel raw material up to the battery material through collaboration among our three businesses of resources, smelting and refining, and materials is one of Sumitomo Metal Mining’s strengths.

Niihama Nickel Refinery

Smelting & Refining BusinessNickelNiihama Nickel Refinery

Located in the city of Niihama in Ehime Prefecture, the Niihama Nickel Refinery is SMM’s only plant in Japan that produces electrolytic cobalt and electrolytic nickel. Since the 1930s, Sumitomo has led the way in nickel smelting and refining in Japan, and successfully started commercial operations in 1939. In 1993, the switch was made to a smelting and refining method for the new generation that boasted high production efficiency and cost competitiveness.

Cerro Verde copper mine(Peru)

Mineral Resources BusinessCopperCerro Verde

Cerro Verde is a open-pit copper mine. Large heavy machineries is used to dig down from the surface.

Hole drilling at the Hishikari Mine

Mineral Resources BusinessGoldHishikari Mine

Before crashing ore through blasting, holes to insert the explosives into are first drilled using a drilling machine.

Hole drilling at the Hishikari Mine

Mineral Resources BusinessGoldHishikari Mine

Before crashing ore through blasting, holes to insert the explosives into are first drilled using a drilling machine.

The Shisaka Island ferry

Smelting & Refining BusinessBesshi Copper MineThe History of Sumitomo Metal Mining

After the smelting and refining facilities were moved to Shisaka Island in the Meiji period as a countermeasure against pollution from the smelter at the Besshi Copper Mine, a ferry provided a link to the island for more than 100 years.

Mineral ore in the area surrounding Cote (Canada)

Mineral Resources BusinessGoldCote

In 2017, SMM acquired an interest in the Cote Gold Project in the state of Ontario in Canada. The project team is working on putting the preparations in place ahead of the start of production in 2023.

Automobile secondary batteries cathode material

Materials BusinessProducts

Demand for automobile secondary batteries is increasing rapidly due to increased electrification of automobiles. Sumitomo Metal Mining can stably produce high-quality cathode material that is essential for automobile secondary batteries.

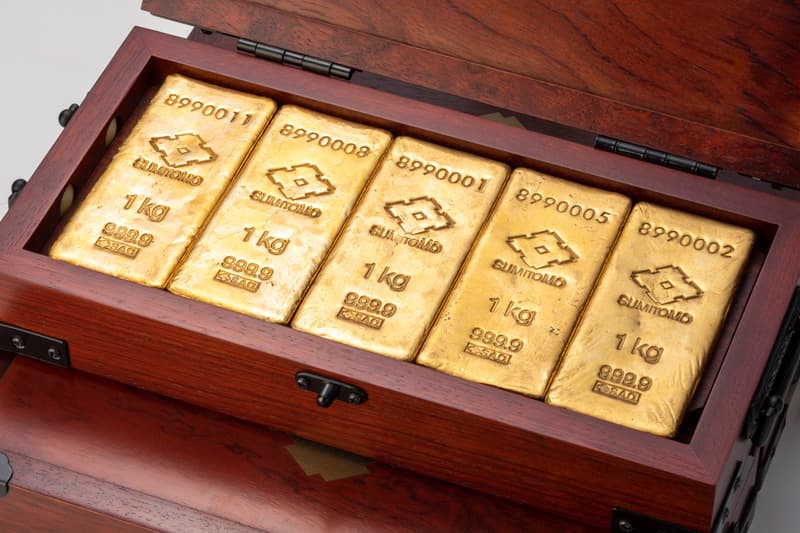

1kg gold bars

Mineral Resources BusinessGoldHishikari MineSmelting & Refining BusinessToyo Smelter & Refinery

Even with the high purity gold ore that the Hishikari Mine boasts, around 50 tonnes are required in order to make a 1kg gold bar.

Drifts with a total length of more than 100km

Mineral Resources BusinessGoldHishikari Mine

The drifts at the Hishikari Mine start from the pithead (entrance) at an altitude of 265m and descend to a depth of 80m below sea level and have a total length of more than 100km.

Pithead of the Hishikari Mine

Mineral Resources BusinessGoldHishikari Mine

The entrance to a mine is called a pithead, and a passage inside a mine is called a drift.

Cerro Verde copper mine (Peru)

Mineral Resources BusinessCopperCerro Verde

Located in Peru, SMM acquired an interest in this copper mine in 2005. Cerro Verde is one of the global top class mines alongside the Morenci copper mine (USA) .

The mined ore of copper grade less than 1% becomes copper concentrate through mineral processing its copper content raised to 23%. Copper concentrates are shipped to Toyo Smelter & Refinery with approximately two-month sea journey and become electric copper of purity more than 99.99% after smelting and refining process.

Mining at the Cerro Verde copper mine(Peru)

Mineral Resources BusinessCopperCerro Verde

Cerro Verde is a open-pit copper mine. Large heavy machinery is used to dig down from the surface.

Cerro Verde copper mine(Peru)

Mineral Resources BusinessCopperCerro Verde

Located in Peru, SMM acquired an interest in this copper mine in 2005. Cerro Verde is one of the global top class mines alongside the Morenci copper mine (USA) .

The mined ore of copper grade less than 1% becomes copper concentrate through mineral processing its copper content raised to 30%. Copper concentrates are shipped to Toyo Smelter & Refinery with approximately two-month sea journey and become electric copper of purity more than 99.99% after smelting and refining process.

Cerro Verde copper mine (Peru)

Mineral Resources BusinessCopperCerro Verde

Located in Peru, SMM acquired an interest in this copper mine in 2005. Cerro Verde is one of the global top class mines alongside the Morenci copper mine (USA) .

The mined ore of copper grade less than 1% becomes copper concentrate through mineral processing its copper content raised to 30%. Copper concentrates are shipped to Toyo Smelter & Refinery with approximately two-month sea journey and become electric copper of purity more than 99.99% after smelting and refining process.

Hole drilling at the Hishikari Mine

Mineral Resources BusinessGoldHishikari Mine

Before crashing ore through blasting, holes to insert the explosives into are first drilled using a drilling machine.

Remains of the Besshi Copper Mine: Third Substation

Besshi Copper MineThe History of Sumitomo Metal Mining

The industrial remains of the Besshi Copper Mine, which had the largest copper deposit in Japan, stretch over a distance of 40km from the mountain to Shisaka Island.

The Hishikari Mine has the highest gold production in Japan

Mineral Resources BusinessGoldHishikari Mine

In 1981, a gold deposit was discovered in a valley surrounded by the abundant nature of Japan’s Kagoshima Prefecture (in present Isa city). Extraction began at the Hishikari Mine there in 1985. The Hishikari Mine continues to boast the highest gold production in Japan.

Coral Bay Nickel Corporation sign(Philippines)

Smelting & Refining BusinessNickelTaganito / Coral Bay

Coral Bay Nickel Corporation(CBNC) is Sumitomo Metal Mining’s group company in Philippines, where our first HPAL plant operates. CBNC produces mixed nickel-cobalt sulfide using the HPAL technology that it successfully commercialized before anyone else in the world, and ships it to its Niihama Nickel Refinery and Harima Refinery.

Toyo Smelter & Refinery Niihama Refining Sect.

Smelting & Refining BusinessCopperToyo Smelter & Refinery

Niihama Refining Sect. used to be a independent plant called Copper Refining Plant, but now is integrated as a part of Toyo Smelter & Refinery.

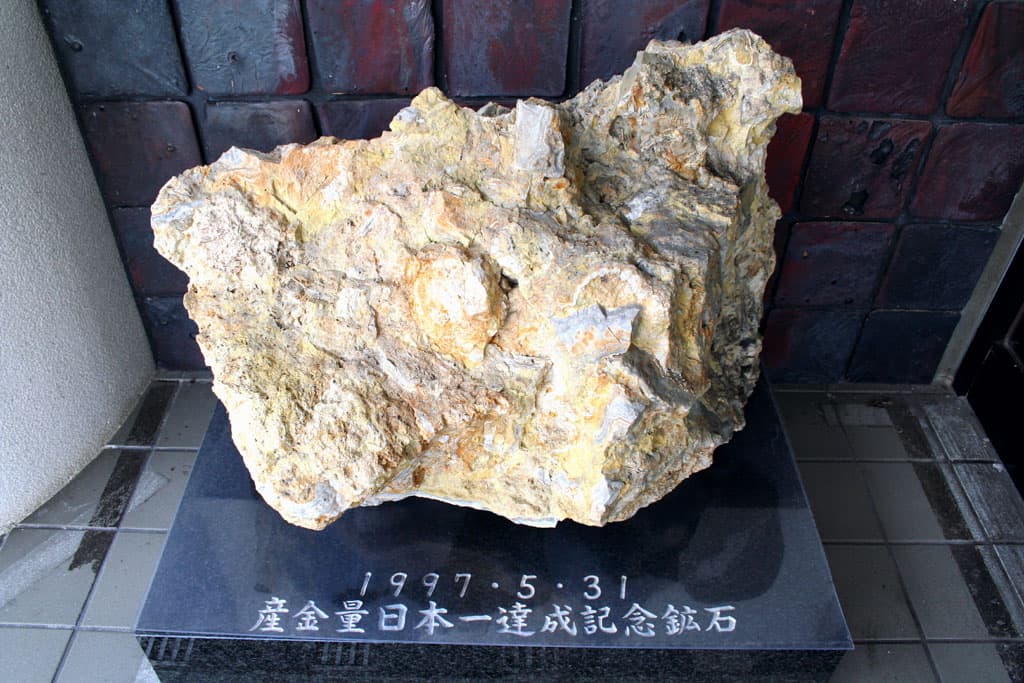

Mineral ore commemorating the mine’s achievement of the highest gold production in Japan

Mineral Resources BusinessGoldHishikari Mine

Owned by Sumitomo Metal Mining, the Hishikari Mine continues to be the most productive gold mine in Japan with an annual production of six tonnes. The photograph shows a piece of mineral ore commemorating the mine’s achievement of the highest gold production in Japan

2nd floor elevator hall at Head Office

The History of Sumitomo Metal Mining

Copper has always been there throughout Sumitomo Metal Mining’s more than 400 years of history and growth, which has seen events including the development of the smelting technique known as “Nanban-buki”, the opening of the Besshi Copper Mine, and the modernization of copper smelters. Copper is used in many locations at the Head Office of Sumitomo Metal Mining, which has carried on the original business of Sumitomo.

Oyamazumi Shrine on the rooftop of Head Office

Besshi Copper MineThe History of Sumitomo Metal Mining

The Oyamazumi Shrine at the Besshi Copper Mine enshrines the deity that protects mines. When the mine was opened in 1691, this shrine enshrined a division of the deity from Oyamazumi Shrine on Omishima Island off the coast of Imabari City. The main deity is Oyamatsumi, and is known as the god of mountains, the god of the sea, and the god of war. An Oyamazumi Shrine has also been established on the roof of the Head Office building to pray for the protection and prosperity of mines.

Harima Refinery

Smelting & Refining BusinessNickelHarima Refinery

Harima Refinery commenced operations in 1966 as a zinc and lead smelter and not is a production base for nickel sulfate.

Hoshigoe-kan multi-purpose training facility

Sustainability

Towards our long-term vision of becoming the world leader in the non-ferrous metals industry, SMM places great importance on improving manufacturing capability. As a base for the development of the human resources essential to achieving this goal, SMM has established the Oji-kan Facility for hazard simulation training and Hoshigoe-kan multi-purpose training facility in the city of Niihama in Japan’s Ehime Prefecture, which hosts core plants and affiliate companies. The photograph shows the outside of the Hoshigoe-kan.

SMM Strategy Planning Training Center: a base for human resource development

Sustainability

As a base to develop the human resources to take Sumitomo Metal Mining into the future, the SMM Strategy Planning Center was opened in September 2010 in the city of Susono in Japan’s Shizuoka Prefecture. This center is used as a venue considering and proposing management strategies full of creativity in a natural environment that is removed from everyday life.

SMM Strategy Planning Training Center: a base for human resource development

Sustainability

As a base to develop the human resources to take Sumitomo Metal Mining into the future, the SMM Strategy Planning Center was opened in September 2010 in the city of Susono in Japan’s Shizuoka Prefecture. This center is used as a venue considering and proposing management strategies full of creativity in a natural environment that is removed from everyday life.

Taganito HPAL Nickel Corporation pointing and calling sign board(Philippines)

Smelting & Refining BusinessNickelTaganito / Coral Bay

Even at Taganito HPAL Nickel Corporation in the Philippines, Japanese-style pointing and calling is practiced to ensure safety.

Remains of the Besshi Copper Mine: Koashidani Theater

Besshi Copper MineThe History of Sumitomo Metal Mining

Built in 1889, the large Koashidani Theater (on top of the stone walls) could host 1,000 and was equipped with a revolving stage. Kabuki performances were provided annually by well-known actors from Kyoto and Osaka for entertainment to those who worked in the copper mine.

Remains of the Besshi Copper Mine: Kanki Shaft

Besshi Copper MineThe History of Sumitomo Metal Mining

In 1690, Tamuki Jyuemon, a clerk at the Yoshioka Copper Mine (Takahashi City, Okayama Prefecture) run by Sumitomo, heard of a promising mineral vein in the mountains of Shikoku. After setting out and traversing a steep pass, following a river to its source, and making his way through dense forests, he finally came upon the outcrop exposed at the surface. Tradition has it that the shaft was named “Kanki” (meaning “joy” in Japanese) because Tamuki Jyuemon and his companions were so delighted with the discovery of the deposit that they hugged one another with joy.

Remains of the Besshi Copper Mine: Ore Bin

Besshi Copper MineThe History of Sumitomo Metal Mining

Extracted copper mineral ore was temporarily placed in the ore bin, and after it was separated in the mineral processing area it was sent to Niihama.

Remains of the Besshi Copper Mine: Entrance to Adit No. 4

Besshi Copper MineThe History of Sumitomo Metal Mining

Operations at the mine started with excavation from the ore vein near the summit of the mountain and proceeded towards the base in pursuit of new ore veins. “Adit” refers to a drift dug horizontally into a mountainside, and the first adit was opened in 1886. The fourth adit was opened at 156m above sea level in 1915 and served as a major artery until the mine closed.

Drops of copper

Smelting & Refining BusinessThe History of Sumitomo Metal MiningCopper

A long time ago, drops of a metal being poured into a cast would naturally harden, and this began to receive attention for the charming shape that would result. The various forms created would invoke a range of different images, and they became prized as “piles of gold.” Sumitomo Metal Mining’s drops of gold, silver, and copper are auspicious ornaments that recreate this form.

Lithium tantalate: supporting communication devices

Materials BusinessProducts

Lithium tantalate is used in SAW devices that contribute to increased quality in smartphones and other such communication devices.

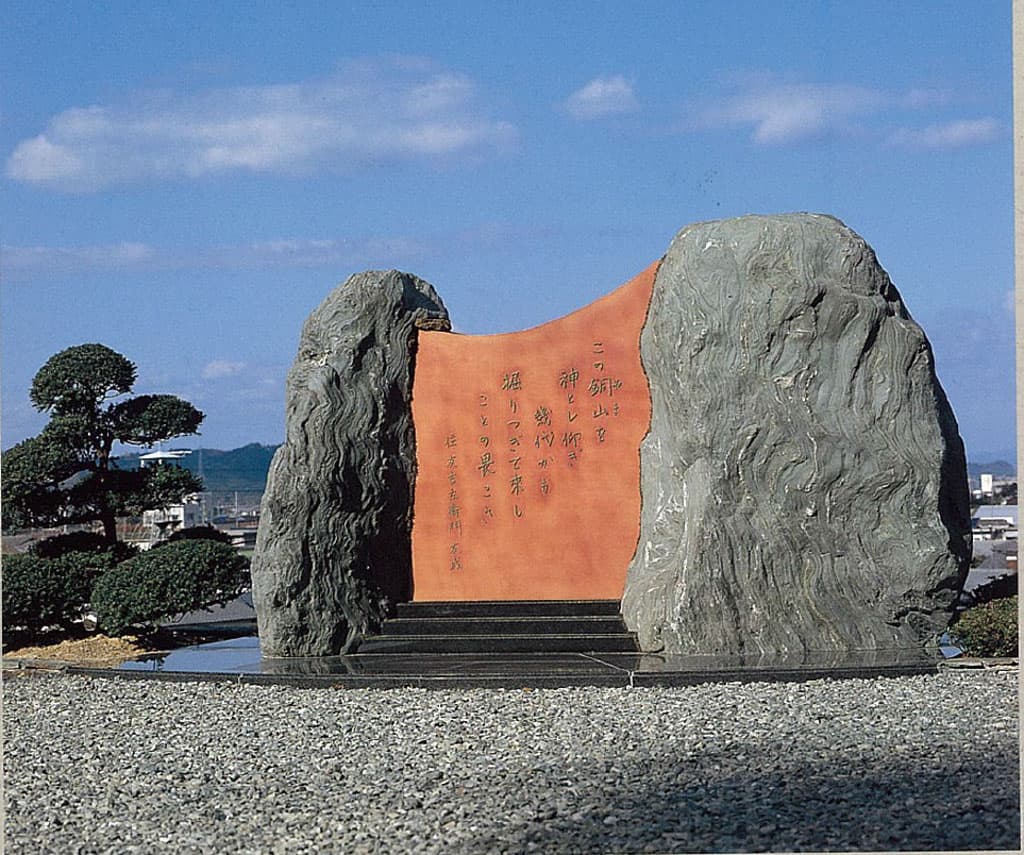

A monument engraved with a poem to mark the closing of the Besshi Copper Mine

Besshi Copper MineThe History of Sumitomo Metal Mining

“We have looked up to this copper mine as a deity and revered it as we have dug it up through the ages” is a tanka poem by Tomonari Sumitomo, the head of the 16th generation of the Sumitomo family. Tomonari was also an Araragi-school poet who went by the name of Kokichi Izumi and was mentored by Mokichi Saito. When the Besshi Copper Mine’s history reached its final page in 1973, Tomonari reflected on the passage of almost 300 years and wrote a poem expressing his emotions and including his reverence for nature and humanity.

The Hishikari Mine is characterized by high-grade mineral ore

Mineral Resources BusinessGoldHishikari Mine

With a content of around 20 grams of gold per tonne of ore, the Hishikari Mine boasts a gold grade among the highest in the world. This is a gold grade around five times higher than the global average (approximately 3-5 grams/tonne).

Besshi Copper Mine Memorial Museum

Besshi Copper MineThe History of Sumitomo Metal Mining

The museum in Niihama City of Japan’s Ehime Prefecture hosts many historical materials from the 283 years of Besshi Copper Mine’s history that are on display to the public. The building is a subsurface structure based on a mine, and the roof is covered with Satsuki (Rhododendron indicum) flowers.

Cerro Verde copper mine guide to surroundings(Peru)

Mineral Resources BusinessCopperCerro Verde

The Cerro Verde copper mine is located at an altitude of 2,700m above sea level. Close by are the port of Matarani where copper concentrate is shipped from and Lake Titicaca, which is known for ruins from the Inca Empire.

Yunoo Onsen

Mineral Resources BusinessGoldHishikari Mine

Underground at the Hishikari Mine, hot spring water with a temperature of approximately 65℃ is expelled along the gold ore vein.

The hot spring water is pumped up from underground and supplied via an approximately six-kilometer pipeline to the local Yunoo hot spring resort.

ASEAN Mineral Awards: Winner

Smelting & Refining BusinessNickelTaganito / Coral Bay

Coral Bay Nickel Corporation was recognized by the Association of Southeast Asian Nations (ASEAN) at the 2019 ASEAN Mineral Awards (AMA) when it was awarded first prize in the metallic and mineral processing category as the best practices in sustainable mineral development.

Winner of the platinum 2019 Presidential Mineral Industry Environmental Award

Smelting & Refining BusinessNickelTaganito / Coral Bay

Coral Bay Nickel Corporation received a platinum (runner-up) Presidential Mineral Industry Environmental Award (PMIEA) from the Philippines’ Department of Environment and Natural Resources in 2019.

Morenci copper mine (USA)

Mineral Resources BusinessCopperMorenci

Located in Arizona state in the USA, the Morenci copper mine is known for being an excellent mine. SMM acquired interest in this mine in 1986, and this formed the spur for fully fledged investment in overseas copper mines.

Lithium nickel oxide (NCA) is essential for electric vehicles

Materials BusinessNickelProducts

Lithium nickel oxide (NCA) is used as the cathode material in lithium ion batteries, and is mostly used in electric vehicles. Integrated production from the nickel raw material up to the battery material through collaboration among our three businesses of mineral resources, smelting and refining, to materials is one of Sumitomo Metal Mining’s strengths.

Exploration work

Mineral ResourcesGoldCopper

SMM’s expert exploration staff, with their exploration skills honed through many years of experience, proactively undertake gold and copper explorations and investigate mining project in which Sumitomo Metal Mining can participate with a focus on areas with high potential in the Pacific rim.

Rehabilitation of tailings dams in the Philippines

Sustainability

Sumitomo Metal Mining puts into practice the group’s corporate philosophy of sustainable co-existence with society and the global environment through its business in various countries around the world. One example of this is the rehabilitation of tailings dams (accumulative sites for the neutralized and stabilized unneeded mineral solids) that have fulfilled their purpose by planting vegetation and returning them to their natural green state.

Former Konomai Mine Stack in Hokkaido

Smelting & Refining BusinessThe History of Sumitomo Metal Mining

The chimney of the former Konomai Mine in Monbetsu City, Hokkaido, was built around 1932 as a boiler chimney for insulating cyanide solution at the Motoyama Smelting Plant. After the war, it was used as an incinerator. After many years of disuse, the smokestack, which stood quietly in the forest, is scheduled to be demolished in September 2024.