Harima Refinery

Operating as a major nickel sulfate production base.

The Harima Refinery used to be a smelter of zinc, lead, indium and other metals since it began operations in 1966. Currently, the plant is transformed to a refinery producing nickel sulfate, which is used as a raw material for rechargeable batteries for hybrid and electric vehicles.

Main products manufactured at the Harima Refinery

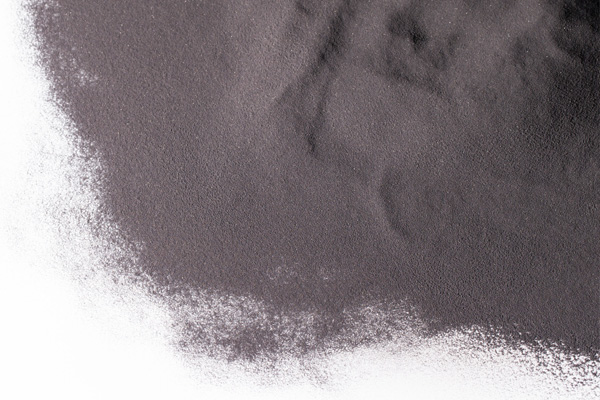

Nickel Sulfate

Used for a wide variety of applications, including coloring aluminum, catalyst, and battery materials, as well as for nickel plating.

Smelting and refining at the Harima Refinery

Raw Materials

Nickel / cobalt mixed sulfide with a 50 to 60% nickel grade produced in Coral Bay Nickel Corporation and Taganito HPAL Nickel Corporation, which are Sumitomo Metal Mining’s subsidiaries, using the HPAL (High Pressure Acid Leach) process is used as raw material.

Smelting and refining process

Production of Nickel Sulfate

STEP1

Pressurized Extraction

Nickel is extracted through directly pressurizing nickel/Cobalt mixed sulfide(MS) matte by air oxidation reaction under high temperatures and pressure, and is made into a mixed nickel sulfate and cobalt solution.

STEP2

Solution Purification

Impurities such as iron and other impurities are removed from a nickel-cobalt sulfate mixture solution using an oxidation-neutralization reaction.

STEP3

Solvent Extraction

Nickel, cobalt, and other impurities are separated using an organic solvent to manufacture pure nickel sulfate solution.

Smelting & Refining Business in Visual Media

Learn about the " Smelting & Refining Business" in pictures with description.

-

Copper casting at the Toyo Smelter & Refinery