Toyo Smelter & Refinery

Carrying on the history of the Besshi Copper Mine

World-class copper plant

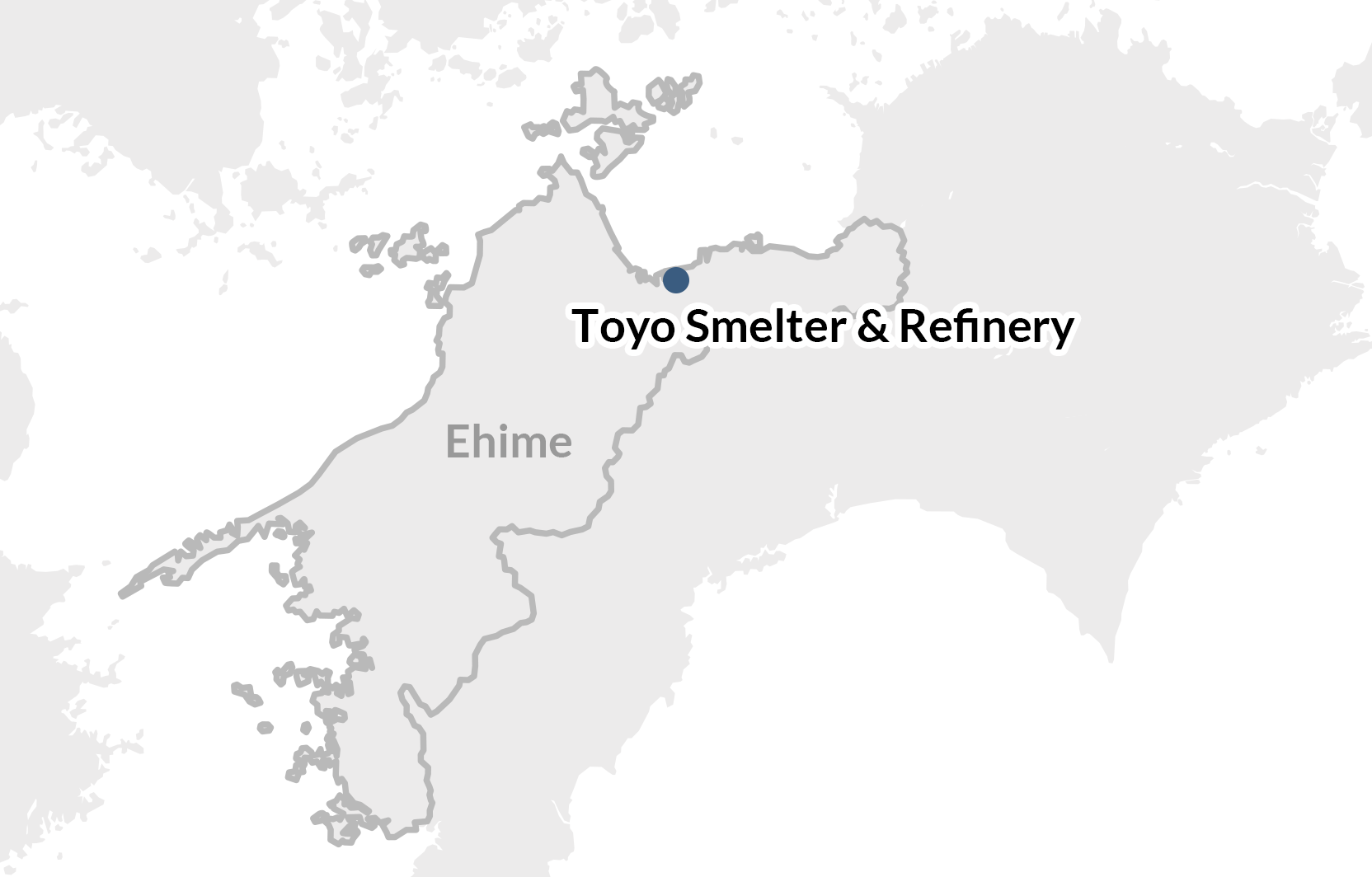

The Toyo Smelter & Refinery, located across the cities of Saijo and Niihama in Ehime Prefecture, began operations in 1971 under the philosophy of "an environmentally friendly and clean smelter." The site of the Besshi Copper Mine, which has been operated by the Sumitomo Group since the Edo period, is located nearby, and the Toyo Smelter & Refinery continues to smelt copper, carrying on the history of the mine. The Toyo Smelter & Refinery has the world largest-class production capacity of electrolytic copper as a smelter with only one flash furnace, also boasts world-class production capability in terms of advanced smelting and refining, production management, and environmental conservation technologies.

Main products of Toyo Smelter & Refinery

Copper Products

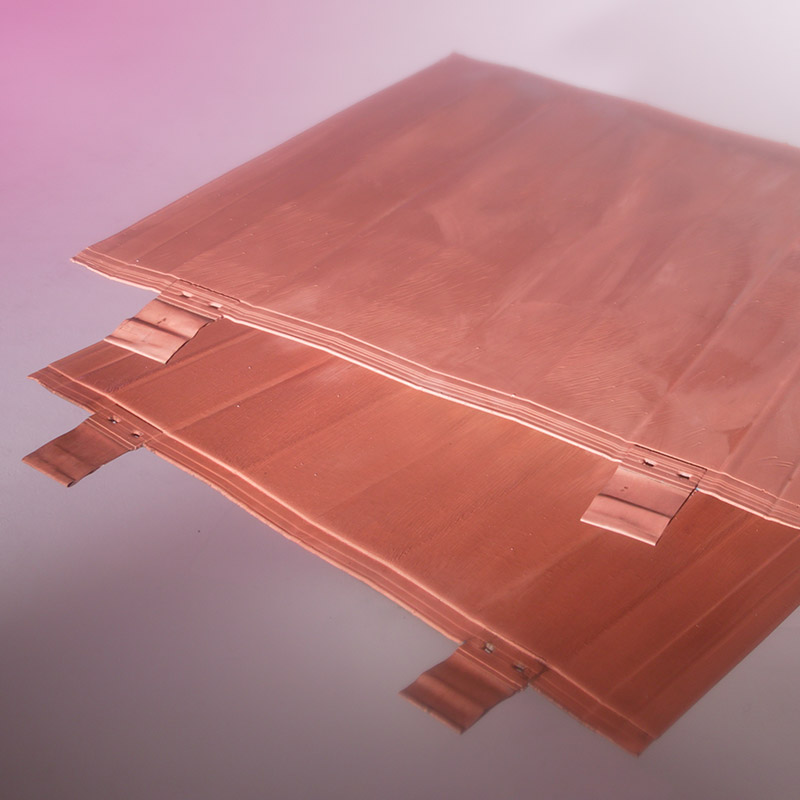

Electrolytic Copper

This is high grade electrolytic copper with a purity of 99.99%.

Slag Sand

Since extraction of sea sand has been progressively banned due to consideration of the environment, Slag Sand is drawing attention as a substitute for concrete fine aggregate material.

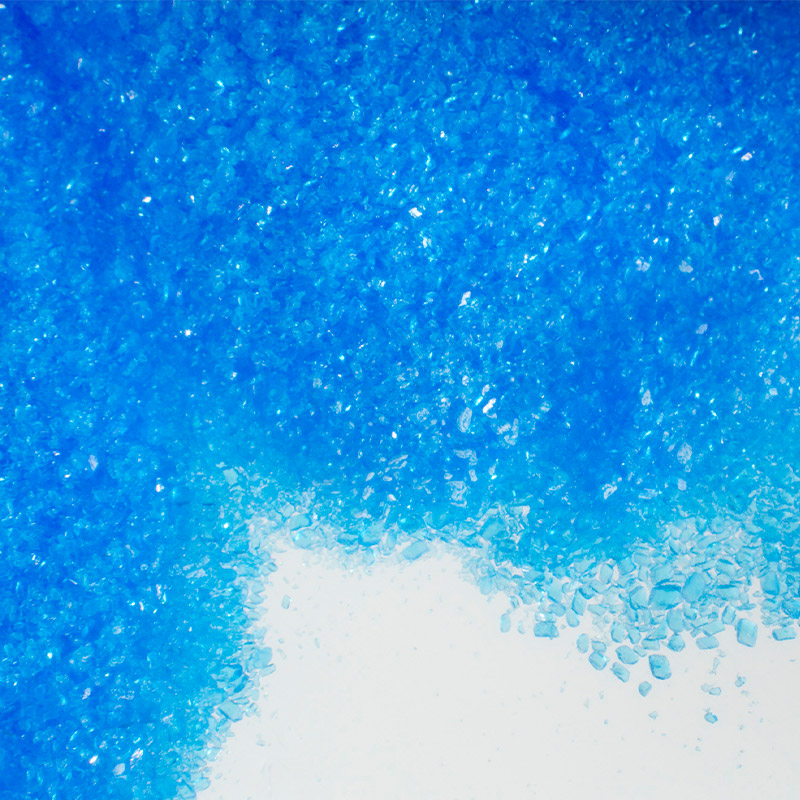

Copper Sulfate

Copper sulfate is mainly used for the copper plating of printed circuit boards.

Metal Products

Gold Ingot

Various sizes of gold ingots are manufactured.

Gold Granule

Features : easily soluble.

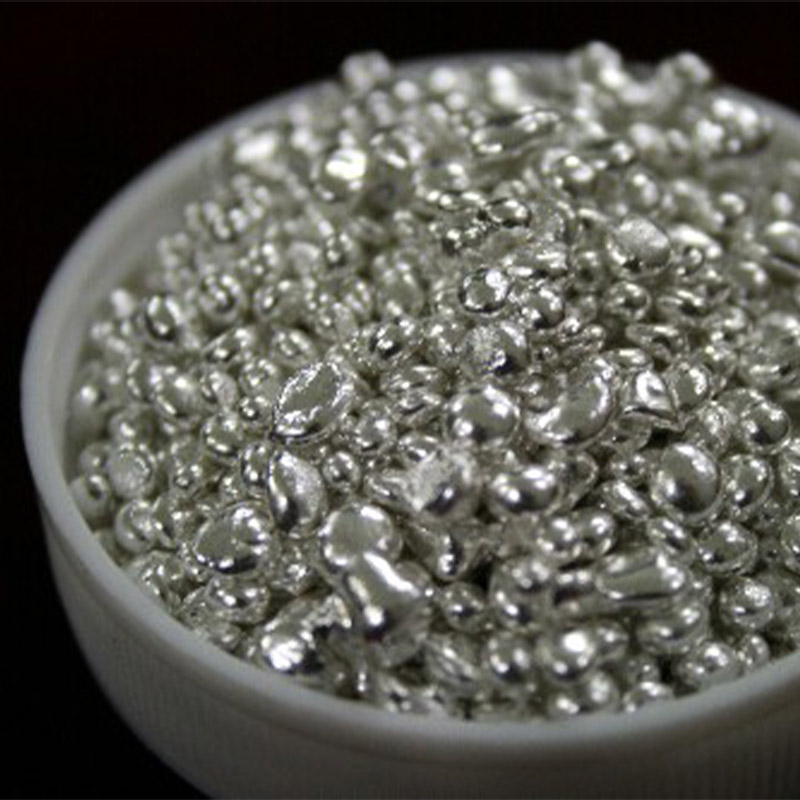

Silver Granule

Features : easily soluble, similar to the corresponding gold product.

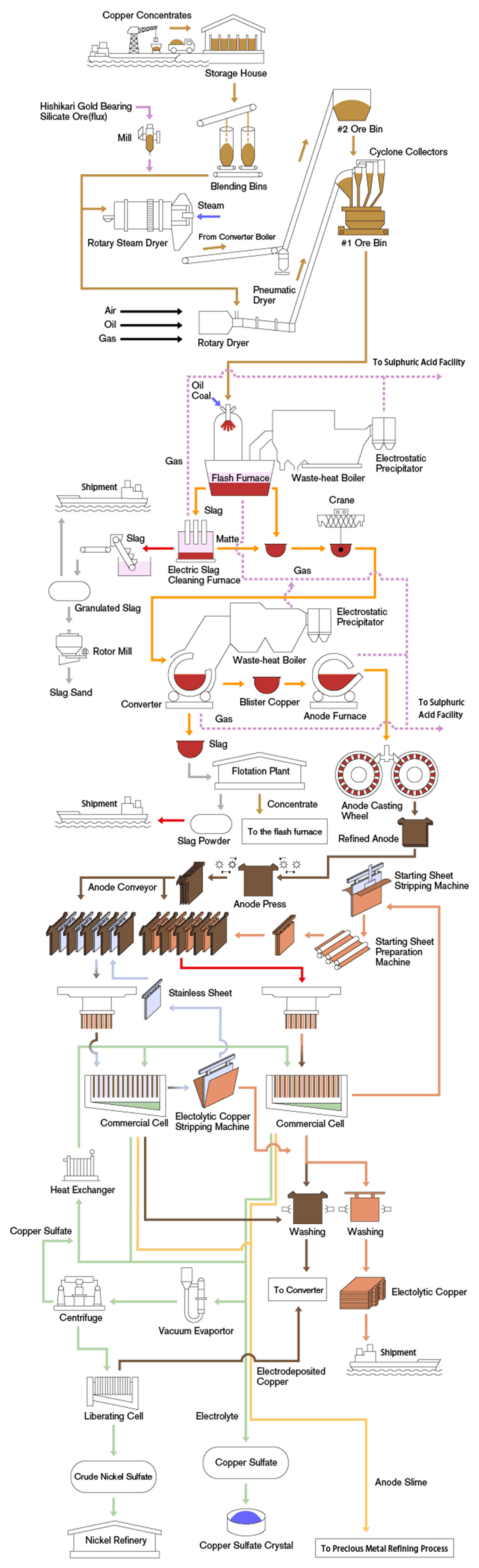

Smelting and refining at the Toyo Smelter & Refinery

Raw Materials

Sumitomo Metal Mining holds stakes in copper mines in North and South America and Australia to ensure a stable ore supply. Mined ore which has a copper grade of less than 1% is turned into copper concentrate with a purity of about 30% at mine site and transported to the Toyo Smelter & Refinery. In addition to copper, copper concentrates contain about 30% each of iron and sulfur, and trace amounts of gold, silver and other precious metals, all of which are recovered. The Toyo Smelter & Refinery also uses gold ore from our own Hishikari Mine (Kagoshima Prefecture) as the solvent used in copper smelting.

Smelting Process

Production of Electrolytic Copper

STEP1

Unloading Copper Concentrate

Copper concentrate to be smelted is carried in by a special carrier and then unloaded from its special berth. Up to 30,000 tonnes class carriers can dock in the berth.

Copper concentrate

Copper grade

20-30%

STEP2

Concentrate Dryer

Since copper concentrate contains about 8% water, it is dehydrated using a dryer. For dehydrating copper concentrate, not only heavy oil but also heat of steam collected in the plant are used, which help to save energy.

STEP3

Flash Furnace

Copper concentrate and gold ore are put in the flash furnace, and hot wind is blown in for them to be oxidized and melted. Because the heat of burning sulfur contents in the copper concentrate melt the sulfur itself and maintain high temperature, the furnace is called flash furnace. Copper that has been concentrated so that its grade is 60 to 65% is called matte. Dependent on the difference in specific gravity, slag is separated from matte.

Matte

Copper grade

60-65%

STEP4

Converter and Anode Furnace

Mattes are sent to the converter. It is condensed to copper purity of 98% by removing sulfur and iron in the converter, then becomes blister copper of purity 99% by adjusting its content in anode furnace.

STEP5

Casting

The blister copper is cast in a mold frame in the anode casting machine and becomes a "refined anode" in the form of a plate weighing about 400 kilograms each.

Refined anode

Copper grade

98%

STEP6

Electrolysis

By two electrolysis methods, the starting sheet method which refined anode and starting sheet alternately in the electrolysis tank and the permanent cathode method using stainless sheet instead of starting sheet, electrolytic copper with a purity of 99.99% are produced.

Electrolytic copper

Copper grade

99.99%

- Recovery of precious metals and minor metals

- Precious metals or rare metals contained in the refined anodes remain as anode slime (deposit) at the bottom of the electrolytic tank and is then sent to the precious metal refining plant.

Toyo Smelter & Refinery in Visual Media

Learn about the Toyo Smelter & Refinery in pictures with description.

-

Copper casting at the Toyo Smelter & Refinery