Recycling of lithium-ion secondary batteries

As automobiles undergo what is expected to be a rapid and long-term shift to electric drive and battery capacity becomes increasingly higher, demand is growing for the copper, nickel, cobalt, and lithium used in lithium-ion secondary batteries (LIBs) for electric vehicles, leading to calls for effective resource recycling.

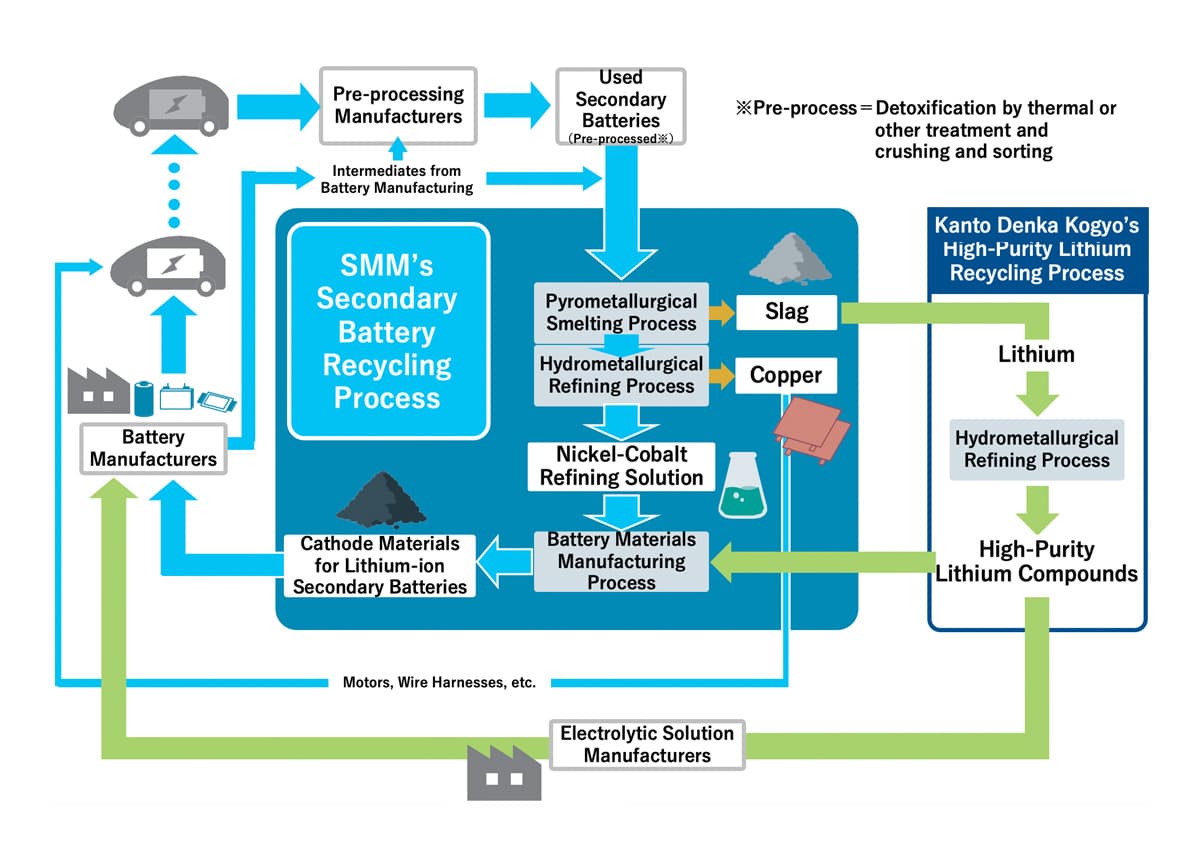

Since 2017, we have been working to recover and reuse the copper and nickel contained in LIBs through a process that combines the Toyo Smelter & Refinery’s copper smelting and refining processes and the Niihama Nickel Refinery’s nickel smelting and refining processes. The recovered nickel, in particular, is processed into a secondary battery cathode material at the Isoura Plant, realizing Japan’s first “battery to battery” horizontal recycling using materials recovered from used LIBs.

In addition to this, we have been promoting LIB recycling research and development and demonstrated in 2021 that cobalt, for which resource depletion is a concern, can also be recovered, purified to a high level, and reused as a raw material for LIB cathode materials. Moreover, through joint development with Kanto Denka Kogyo Co., Ltd., we established technology that recycles lithium from slag containing lithium into high-purity compounds in 2022, successfully developing a new process for horizontal recycling of copper, nickel, cobalt, and lithium.

In evaluations of battery performance by battery user Primearth EV Energy Co., Ltd., it was demonstrated on the product level that the performance of batteries using LIB cathode materials manufactured through this process is equal to that of batteries manufactured from conventional raw materials, primarily derived from natural resources.

We are currently studying the commercialization of battery recycling with the aim of establishing a system for processing 10,000 tons per year during the term of the 2024 3-Year Business Plan (FY2025–2027). In parallel with this, we are also working to develop technology for reducing CO2 emissions from the perspective of carbon neutrality. If this new process makes it possible to reuse valuable metals as resources on a commercial basis, it can be expected to make a further contribution to resource recycling to combat global resource depletion.

Looking ahead, we will continue to actively work on “battery to battery” horizontal recycling and will contribute to the formation of a sustainable circular society and the strengthening of resource recycling to combat global resource depletion.

Recycling Flow

Companies with Partnership Agreements

To establish a supply chain for LIB recycling, we have concluded partnership agreements with the following companies for a used LIB collection system.

(As of April 1, 2024)

MM&KENZAI Corporation, OONO DEVELOPMENT CO., LTD, Sanyo-Rec Co., Ltd., Toho Zinc Co., Ltd., DOWA ECO-SYSTEM CO., LTD., TOYOTA TSUSHO MATERIAL INCORPORATED, Nippon Magnetic Dressing Co., LTD., Nippon Recycle Center Corp., MATSUDA SANGYO CO., LTD.