Emission Reduction for the Sumitomo Metal Mining Group

Roadmap Toward Achieving Carbon Neutrality by 2050

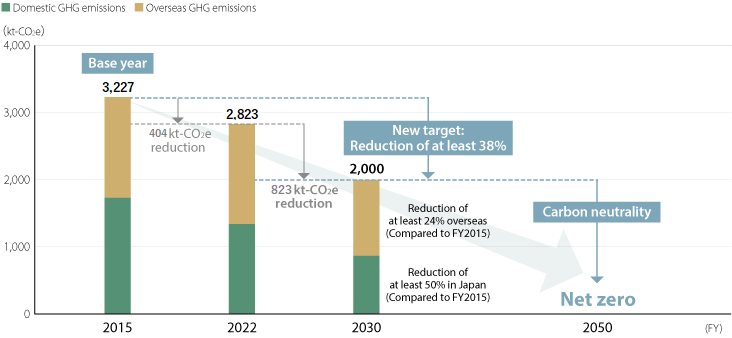

With the aim of achieving net-zero GHG emissions in 2050, the SMM Group set reduction targets for FY2030, formulated a roadmap of action to take through 2050, and announced it in December 2023. The interim reduction targets for FY2030 are a reduction of at least 38% (at least 50% in Japan and at least 24% overseas) with FY2015 as the base year and emissions of no more than 2,000kt-CO2.

■ Roadmap to Net-Zero GHG Emissions (as of December 2023 announcement)

Measures to Achieve Carbon Neutrality by 2050

In the lead up to FY2030, we will take action to maximize the use of existing technologies including comprehensive energy conservation and increases in efficiency, fuel conversion of fossil fuels, and expanded introduction of renewable energy. To achieve carbon neutrality by FY2050, we will tackle the challenges of developing innovative technologies for smelting and refining processes, which are currently difficult to reduce emissions from. Based on the premise of innovation and social implementation of decarbonization technologies, we will also work to introduce new technologies such as next-generation energy and carbon dioxide capture and storage.

Measures for Achieving FY2030 Targets

Regarding the FY2030 interim targets, based on the FY2024 results, we expect a reduction of 41 kt-CO2e due to business plans, 63 kt-CO2e through energy conservation and higher efficiency, 101 kt-CO2e through fuel conversion, and 151 kt-CO2e through improvement of the emission coefficient for procured electric power. We aim to achieve our FY2030 target of 2,000 kt-CO2e, corresponding to a 38% reduction compared to FY2015.

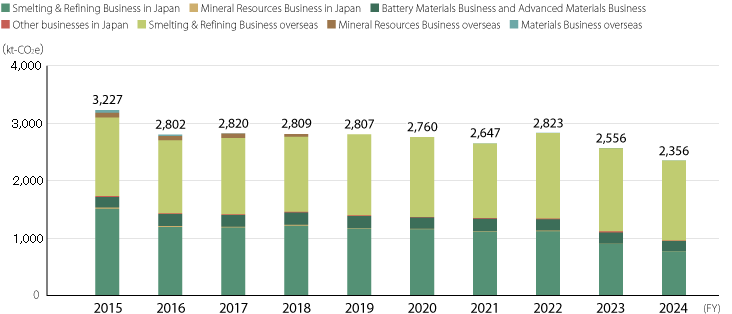

■ GHG Emissions

GHG Emissions (Scope 1 and 2)

GRI 305-1 / 305-2 / 305-5

The SMM Group’s GHG emissions in FY2024 were 2,356 kt-CO2e, a year-on-year decrease of 200 kt-CO2e resulting from a decline in production volume, fuel conversion from heavy oil to LNG, and improvement of the electric power CO2 emissions coefficient. In addition, direct GHG emissions reductions from energy-saving measures and fuel conversion in FY2024 were 33kt-CO2e. Additionally, the Kashima solar power plant operated by SMM helped to reduce emissions by 1.6 kt-CO2e in FY2024.

We had published the trends of energy and GHG emissions intensity indices (reporting boundary: refining & smelting business in Japan) up to the Sustainability Report 2024. However, in light of the global movement—including Japan-toward reducing total GHG emissions, we have reviewed our KPI for GHG emissions intensity reduction and have decided to discontinue the disclosure of these trends starting from the 2025 report.

Scope 1: Direct GHG emissions generated by a business (due to fuel consumption, industrial processes, etc.)

Scope 2: Indirect GHG emissions generated through the use of electricity, heat, and steam supplied by other companies

Scope 3: Indirect GHG emissions not covered by Scope 1 or 2 (emissions from other companies with a connection to the business’ activities)

■ GHG Emissions1 (Scope 1 and 2 )

- 1Figures are rounded to the nearest whole number, so totals may not match

The quantification of GHG emissions is subject to uncertainties in the measurement of activity data, in the determination of emission factors, and in the scientific determination of the global warming potential

Both Japan and overseas figures are calculated based on the GHG Protocol, and emission factors are based on the Japanese law “Act on Promotion of Global Warming Countermeasures”

For calculating GHG emissions from domestically purchased electricity, adjusted emission factors provided by the electricity suppliers are used

For calculating GHG emissions from overseas purchased electricity, country-specific emission factors from the IEA Emissions Factors at that point in time are used

Scope 3 Measures

GRI 305-3

Our Scope 3 GHG emissions for FY2024 were 4,950 kt-CO2e. This was calculated using the emissions output level published by the National Institute of Advanced Industrial Science and Technology database (AIST-IDEA) and the Ministry of the Environment (secondary data). However, we are moving forward with replacing this (improving calculation accuracy) with the emissions output level from business partners’ results (primary data), which allows for calculation of emissions that is more in line with actual circumstances than secondary data. Specifically, we are promoting a shift to primary data from Category 1, which makes up over 80% of our Scope 3 emissions, by communicating with business partners, as well as asking our business partners about their GHG emission reduction targets and the status of their initiatives, to set our Scope 3 emissions reduction targets. As for the state of progress of these initiatives, we conducted a survey of important Category 1 suppliers in FY2024 and collected information including each company’s GHG emissions per product and their reduction targets.

Figures are rounded to the nearest whole number, so totals may not match

■ Scope 3 Emissions1 and Percentage of Overall Emissions

| Category | Reporting boundary | Emissions (kt-CO2e) |

Percentage | Calculation method |

|---|---|---|---|---|

| Total Scope 3 | 4,950 | 67.8% | ||

| 1 Purchased goods and services | SMM Group | 4,262 | 58.3% | Σ (weight of key raw materials x emissions intensity)2 |

| 2 Capital goods | SMM Group | 431 | 5.9% | Σ (amount of capital expenditures x emissions intensity x 1.05)3 Capital expenditures include construction in progress, used equipment, and intragroup transactions |

| 3 Fuel- and energy-related activities not included in Scope 1 or Scope 2 | SMM Group | 226 | 3.1% | Σ (electricity and fuel consumptions x emissions intensity [electricity3, fuel2]) |

| 4 Upstream transportation and distribution | Reference for Calculation method | 20 | 0.3% | Emissions from domestic transportation are calculated based on the Japanese laws the “Act on Rationalizing Energy Use” and “Act on Promotion of Global Warming Countermeasures.” |

| 5 Waste generated in operations | SMM Group - Japan | 7 | 0.1% | Σ (amount of waste by type (major sites in Japan) x emissions intensity by waste type)3 |

| 6 Business travel | SMM Group - Japan | 1 | 0.0% | Σ (number of employees (major sites in Japan) x emissions intensity)2 |

| 7 Employee commuting | SMM Group - Japan | 3 | 0.0% | Σ (number of employees (major sites in Japan) x number of business days x emissions intensity)3 |

| 8 Upstream leased assets | — | Not applicable4 | — | — |

| 9 Downstream transportation and distribution | — | Not applicable5 | — | — |

| 10 Processing of sold products | — | Not applicable5 | — | — |

| 11 Use of sold products | — | Not applicable5 | — | — |

| 12 End-of-life treatment of sold products | — | Not applicable5 | — | — |

| 13 Downstream leased assets | Reference for Calculation method | 0.1 | 0.0% | Σ (electricity and gas consumption by tenants of the Head Office building x emissions intensity)6 |

| 14 Franchises | — | Not applicable7 | — | — |

| 15 Investments | — | Not applicable8 | — | — |

- 1The quantification of GHG emissions is subject to uncertainties in the measurement of activity data, in the determination of emission factors, and in the scientific determination of the global warming potential

- 2For emissions intensity, we used values from the National Institute of Advanced Industrial Science and Technology’s IDEA Ver. 3.5 (IPCC2021 without LULUCF AR6)

- 3For emissions intensity, we used values from the Database for Calculating GHG Emissions of the Supply Chain, (Ver. 3.5), prepared by the Ministry of the Environment and the Ministry of Economy, Trade and Industry in Japan

- 4Not applicable as it is included in calculations of Scope 1 and 2 emissions

- 5This category is not applicable because it is difficult to calculate emissions since our products are mainly non-ferrous metals and highly advanced materials, which have diverse applications after sales destinations, and each application has different GHG emission characteristics

- 6Emissions intensity was calculated based on the list of calculation methods and emission factors of the Ministry of the Environment’s Greenhouse Gas Emissions Calculations Reporting and Publication System

- 7Not applicable as we do not operate any franchise businesses

- 8Not applicable as it is the disclosure of information on investments for profit

Using Internal Carbon Pricing

The SMM Group has established Internal Carbon Pricing (ICP) to promote the development of decarbonization technologies and capital investment and has introduced an ICP system that reflects the effects of GHG reduction in investment decisions. ICP was introduced in September 2020, and we have been actively making decarbonization investments at our business sites using this system. Specifically, in addition to energy-saving investments such as the introduction of LED lighting and the replacement of air conditioning equipment with highly efficient models, we are also switching to change to non-fossil fuel power sources and actively taking on challenges that were previously difficult under conventional investment standards, including the introduction of solar power and the conversion of fuel from heavy oil to LNG. Going forward, we will continue to review the ICP price as necessary in response to changes in social conditions and further promote decarbonization.

| ICP price | Investment projects subject to ICP1 | Anticipated CO2 emissions reduction2 |

|---|---|---|

| JPY20,000/t-CO2 | 65 | 157kt-CO2/year |

- 1Covers investments for which the application of the system was decided between FY2021 and FY2024

- 2 Projected CO2 reductions are calculated based on normal operating conditions. As this includes investments that will be implemented from FY2024 onward, the period in which effects manifest and the period in which application was decided are not concurrent

- Fuel transition from heavy oil to LNG with low CO2 emissions, boilers at the Niihama Nickel Refinery and Isoura Plant, steam heating equipment and drying equipment at the Toyo Smelter & Refinery, and other equipment are being converted in stages from heavy oil to LNG, cutting CO2 emissions by 20% to 30%.

- Utilization of biomass as an alternative to fossil fuels

At Coral Bay Nickel Corporation and Taganito HPAL Nickel Corporation, woody biomass co-firing tests in coal-fired power generating facilities (in-house power generation) have been underway since FY2023. From FY2024, we also began co-firing tests with biomass in kilns at Hyuga Smelting Co., Ltd. and Shisaka Smelting Co., Ltd. Going forward, we will address issues such as stable operation when the biomass co-firing ratio is increased and the stable procurement of biomass required for substitution and will continue to promote CO2 reduction through the use of biomass. - Switch to Electricity Generated with Renewable Energy for Procured Electric Power

The SMM Group is switching in stages to electricity generated with renewable energy at domestic sites. In FY2024, Hyuga Smelting Co., Ltd., Shinko Co., Ltd., SMM Precision Co., Ltd., and GRANOPT Co., Ltd. have switched to renewable energy for all or part of their electricity consumption, and 68% of the electric power purchased from general electricity transmission and distribution utilities has become renewable energy. We will continue to promote the transition with the aim of achieving 100% renewable energy for all procured electricity by FY2030.

Development of Innovative Smelting and Refining Processes

For the Group to achieve carbon neutrality by 2050, it will be necessary to make improvements to innovative smelting and refining processes that dramatically reduce GHG emissions in the smelting and refining business, a main source of GHG emissions. To this end, we are developing new low-carbon nickel smelting and refining technologies, including the development of hydrogen reduction technology for nickel oxide ore smelting, as well as direct lithium extraction methods for recovering lithium from salt lakes.

Hydrogen reduction method

This recovery method recovers reduced nickel metal from nickel oxide ore using hydrogen, which had been considered difficult in the past. By investigating the feasibility through fundamental testing, we achieved the target of recovering reduced nickel metal. We are currently developing the process as a whole, including investigation of equipment to achieve recovery, and aim to start pilot testing by 2030.

Lithium Recovery from Salt Lakes (Direct Lithium Method)

The conventional lithium recovery process used large volumes of chemicals that generate large amounts of CO2, such as hydrated lime, but we developed a new direct lithium extraction (DLE) technology that uses small amounts of absorbents to selectively recover lithium, which leads to reduced CO2 emissions.

We are currently verifying the reliability of the process at a pilot plant installed in Chile, South America, improving the absorbent with the aim of completion by FY2030.