Hyuga Smelting Co., Ltd.

Hyuga City, in Miyazaki Prefecture, is an industrial city located in the center of Kyushu that contains the port of Hososhima, the gateway to the sea. We, as Hyuga Smelting Co., Ltd. (Equity ratio: Sumitomo Metal Mining 60%,NIPPON STEEL Stainless Steel Corporation 25%, Mitsui & Co., Ltd. 15%), utilize this advantageous location to produce ferronickel, while maintaining a harmonious balance with the beauty of nature.

Main products manufactured at Hyuga Smelting Co., Ltd.

Ferronickel Shot

Raw material for stainless steel.

Green Sand

This is an artificial sand product and is used as a solvent in the manufacture of steel and ferroalloy, and as a material for port and harbor civil engineering and ground improvement.

Applications

Ferronickel is an alloy made from iron and nickel, and it becomes the raw material of stainless steel. Since stainless steel has a beautiful luster and it does not rust, it is used for household utensils such as spoons and forks, as familiar examples, and for building materials for automobiles, buildings, houses, etc. Additionally, it is also heavily used for industrial purposes due to its acid-proof and heat-proof properties.

Smelting and refining at the Hyuga Smelting Co., Ltd.

Raw Materials

Sumitomo Metal Mining imports nickel ore (nickel grade approx. 2%) mainly from New Caledonia.

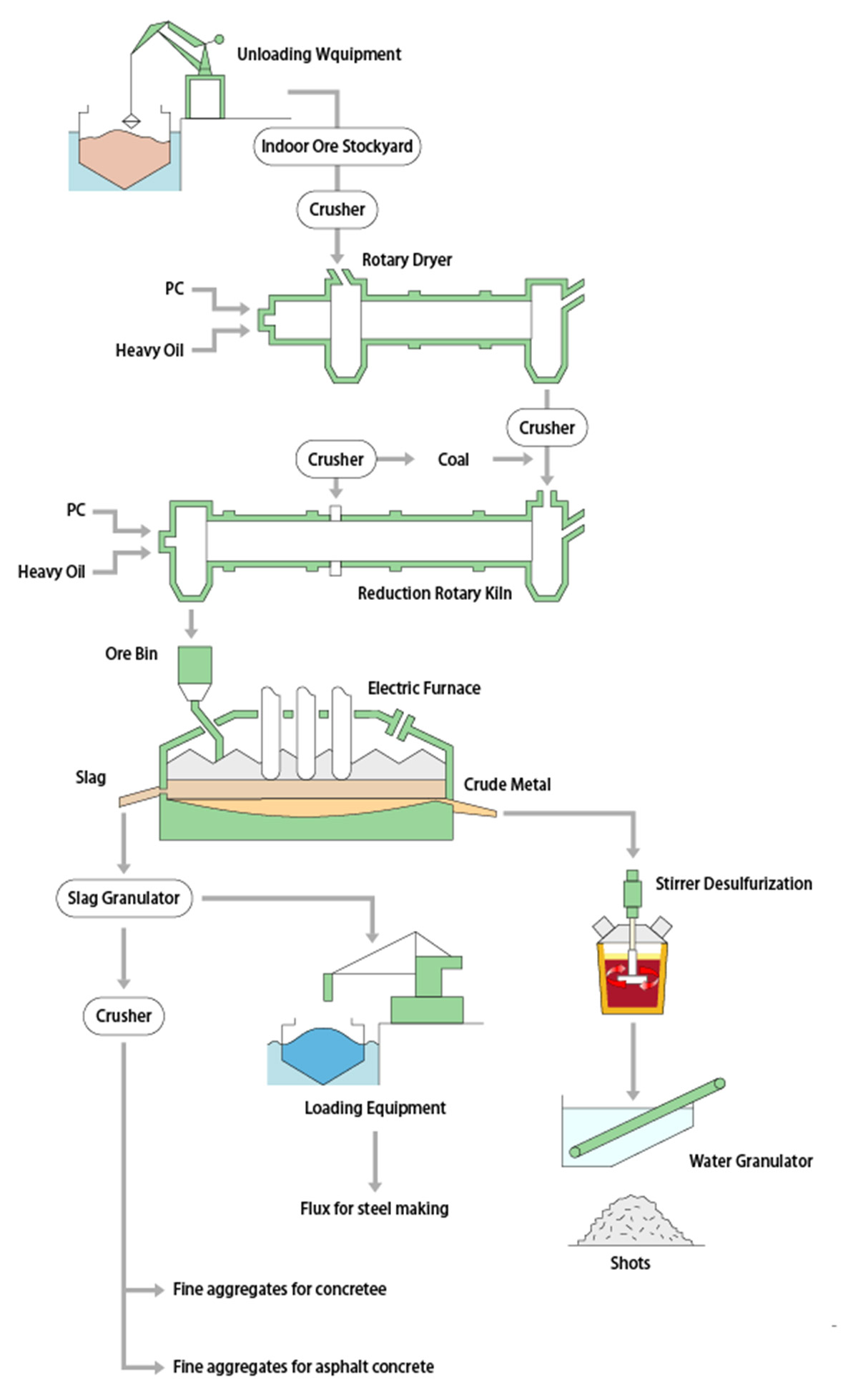

Smelting and refining process

Production of ferronickel

STEP1

Unloading

Raw material ore, transported by an ore carrier, is unloaded by 2 cranes at the ore quay.

STEP2

Drying

Since nickel ore contains a large amount of water, it is first dried using a dryer.

STEP3

Thermally Dehydrated

Ore is charged into the rotary kiln together with coal, and is thermally dehydrated (sintered) by coal combustion and made into calcined ore.

STEP4

Electric Furnace

The calcined ore that comes out of the rotary kiln is charged into an electric furnace while maintaining a high temperature. The calcined ore is separated into metal and slag through heating and reductive dissolution by electricity and coal. The slag will be water-granulated and distributed as steel solvent or aggregate (product name: green sand).

STEP5

Sulfur removal

The metal produced in the electric furnace (crude ferronickel) contains sulfur as an impurity. In the Stirrer Desulfurization, this sulfur is removed using calcium carbide.

STEP6

Casting Machine

Liquid ferronickel is made into shot form and is shipped.

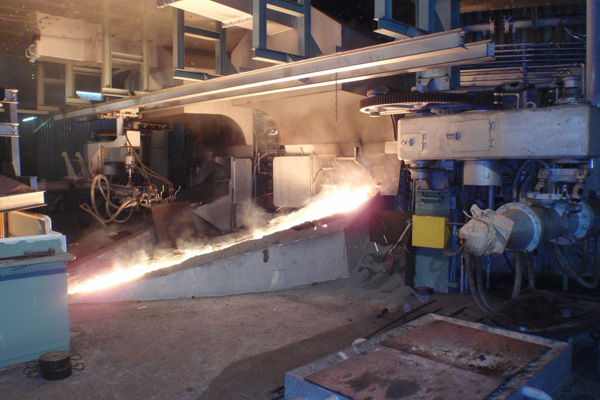

Smelting & Refining Business in Visual Media

Learn about the " Smelting & Refining Business" in pictures with description.

-

Copper casting at the Toyo Smelter & Refinery