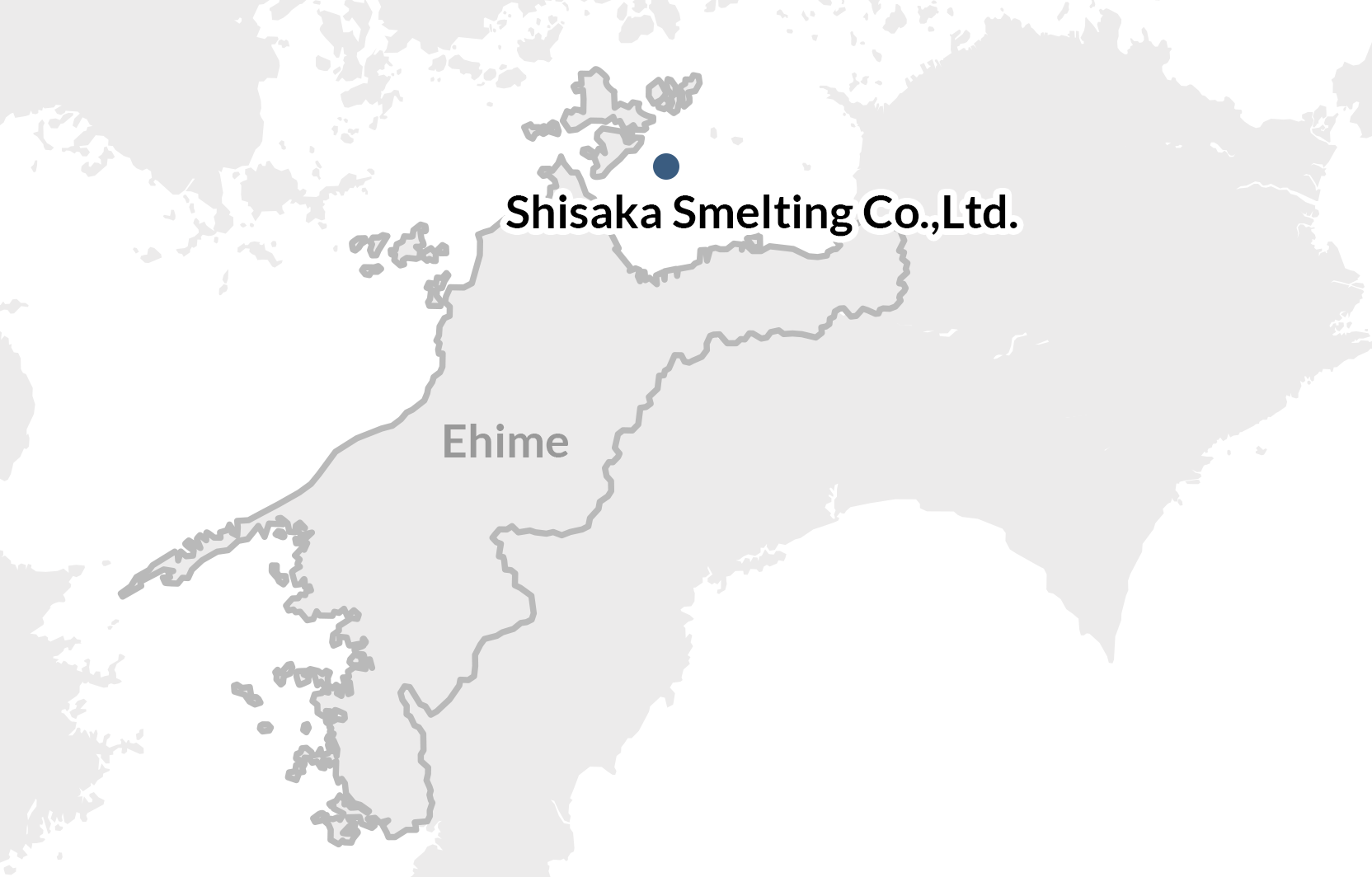

Shisaka Smelting Co.,Ltd.

Shisaka-jima is located approximately 20 km off the coast of Niihama, Ehime. As the name indicates "four islands", Shisaka-jima is the common name for Mino-shima, Yano-shima, Myojin-jima and Nezumi-jima islands. The Shisaka Smelting Co.,Ltd. is located on Yano-shima island. In the Shisaka Smelting Co.,Ltd., the recycling business of recovering zinc contained in steelmaking dust is performed using refining technologies, while placing first priority on the protection of the natural environment.

Main products at Shisaka Smelting Co., Ltd.

Zinc Oxide Pellet

Granulated zinc oxide which is raw material of metal zinc.

Iron Contained Pellet

Pellets containing abundant metal iron. Distributed as iron raw material, etc.

Smelting and refining at the Shisaka Smelting Co.,Ltd.

Raw Materials

Steelmaking dust generated during refining processes in electric furnaces is used as the main raw material.

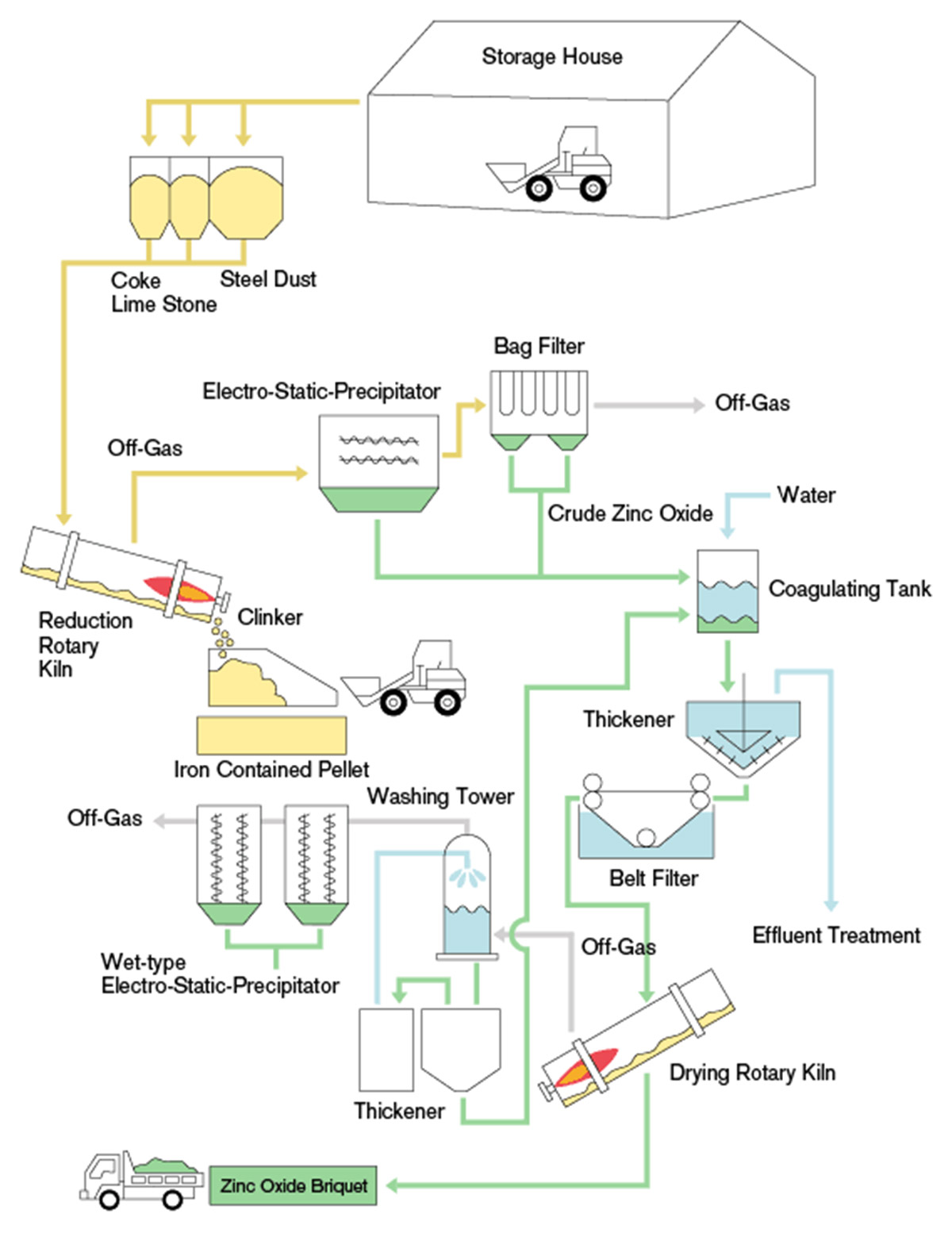

Smelting and refining process

Production of zinc

STEP1

Unloading

Raw material steelmaking dust is transported by a specialized carrier, and unloaded on the ore quay

Copper smokestack

Zinc content

20%

STEP2

Reduction Roasting

The raw material loaded onto the ore quay is heated up to 1200 degrees C in a reduction rotary kiln together with coke and flux, etc., to reduce and volatilize zinc.

STEP3

Hydrometallurgical Process

The reduced and volatilized zinc is recovered as crude zinc oxide and hydrometal-lurgically processed in a coagulating tank, thickener, and belt filter to remove impurities from it.

STEP4

Heated-air drying, Briquetting

Hydrometal-lurgically processed crude zinc oxide is heated up in a drying rotary kiln and made into zinc oxide pellets

zinc oxide (ZnO)

Zinc content

Approx. 60%.

Smelting & Refining Business in Visual Media

Learn about the " Smelting & Refining Business" in pictures with description.

-

Copper casting at the Toyo Smelter & Refinery