Management and Reduction of Chemical Substances

Approach to Chemical Substance Management

Because chemicals are frequently handled in the SMM Group, we have established a chemical substance management system within the environmental management system (EMS) at all business sites under divisional jurisdiction. For example, when a business site intends to handle a new chemical, it conducts a preliminary study that covers hazard statements, laws and regulations, and other applicable information, and deliberates in a meeting at the business site before deciding whether to adopt the handling of said chemical. In addition, the business divisions and Safety & Environment Control Department cooperate with requests for preliminary consultation and verification from the business site.

Further, we also provide information on safe handling for all chemicals transferred or provided to customers or to the other business sites in the SMM Group using safety data sheets (SDS)1 which conform to the Globally Harmonized System of Classification and Labelling of Chemicals (GHS)2 regardless of whether or not we are legally obligated to do so. When developing new materials, we strive to develop materials that customers can use safely and with peace of mind. We review development themes taking into account the toxicity of contained substances, including as pertains to domestic and international regulations for final products as well as the environmental impact of production processes.

Regarding emissions into the atmosphere and water, in order to comply with statutory regulations relating to air and water pollution and further reduce emissions of chemical substances, business sites individually set targets and take action. In FY2024, we continued implementing measures based on the hazardous substance emission reduction targets set by each facility.

- 1Safety data sheet (SDS): A document listing information on a chemical, including the chemical substance, the product name, the supplier, hazards, safety precautions and emergency procedures

- 2The Globally Harmonized System of Classification and Labeling of Chemicals (GHS): A system for classifying chemicals based on the type and degree of hazards and toxicity they pose, chemical labeling, and safety data sheet provision in accordance with a set of internationally agreed upon rules

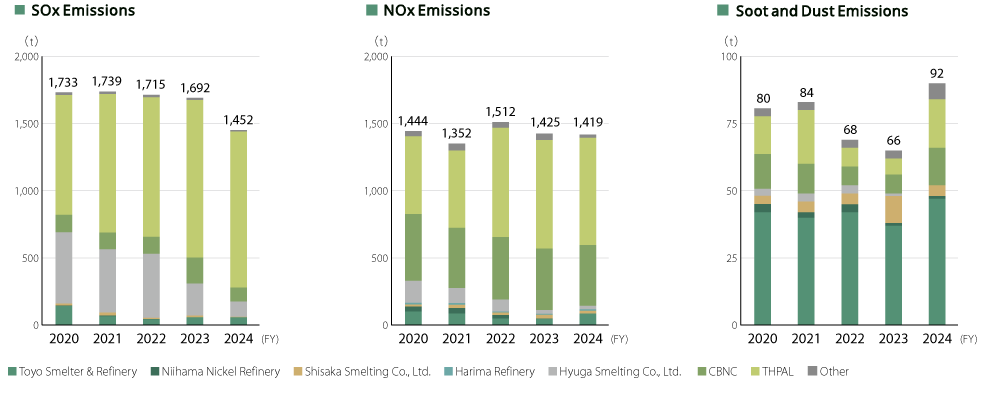

Release into the Atmosphere1

GRI 305-7

SOx emissions in FY2024 decreased by about 14% year on year. The main factors in this decrease were a reduction in the amount of processed raw materials by Hyuga Smelting Co., Ltd. and the degradation of sulfur (S) in coal used by Coral Bay Nickel Corporation (CBNC). A partial increase in NOx emissions was seen due to an increase in the amount of C heavy oil used at Toyo Smelter & Refinery, but the level used by the Group as a whole was nearly the same as the previous fiscal year. Soot and dust emissions increased by about 40% year on year. The main factors in this include an increase in exhaust gas due to high-capacity operations at CBNC, higher density of boiler exhaust gas, and problems with electric dust collectors that occurred at Taganito HPAL.

- 1All emissions are calculated based on flue gas measurement results.

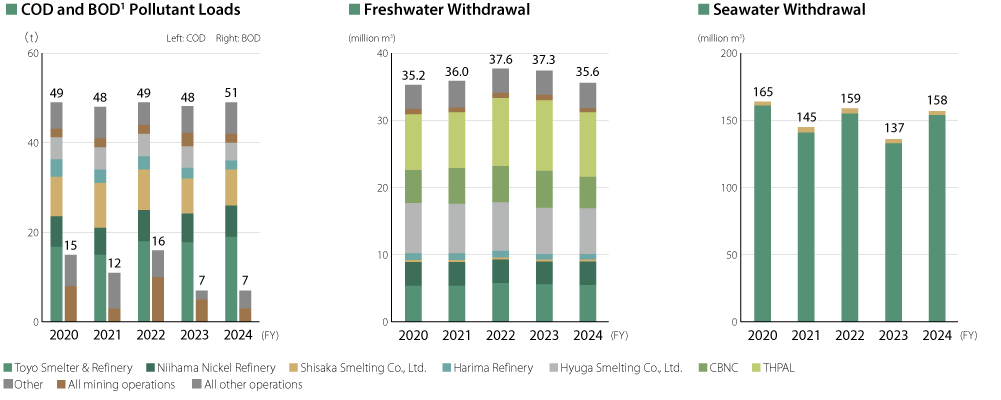

Discharge into Water

GRI 303-2 / 303-3 / 303-4

Many SMM Group business sites are located along Japan’s Seto Inland Sea and are subject to controls on the total amounts of COD1, nitrogen, and phosphorous emissions under the Act on Special Measures Concerning Conservation of the Environment of the Seto Inland Sea. In addition, we adhere to the discharge standards of the Water Pollution Prevention Act and have not had any violations in this area.

- 1COD (chemical oxygen demand): Measured for discharge into seas, including discharge into rivers flowing into enclosed seas

- 1BOD (biochemical oxygen demand): Measured for discharge into rivers, excluding discharge flowing into enclosed seas

Release Control for Chemical Substances1

GRI 305-6

An overview of releases and transfers of chemical substances based on Japan’s Pollutant Release and Transfer Register (PRTR) system in FY2024 is as follows. The number of data-submitting sites in the SMM Group was 24 (23 in FY2023). The Group had 45 (44 in FY2023) substances requiring registration. The total released and transferred amount (releases + transfers) came to 2,450 t, a decrease of about 7% compared with FY2023. This was mainly due to a decrease in the volume of iron clinker2 to be disposed as industrial waste after being generated as a by-product at Shisaka Smelting Co., Ltd. and a decrease in the volume of manganese transferred off-site. However, discharges into water increased by about 12% due to a rise in the density of boron included in the wastewater from the Hishikari Mine, and overall discharges also increased by about 11% year on year. There were no releases of ozone layer depleting substances.

- 1Industrial waste treatment is commissioned to Group companies and industrial waste is recycled for use as raw material. Accordingly, chemical substances transferred off-site include some substances which were effectively not discharged outside the Group, such as nickel compounds as well as cobalt and cobalt compounds.

- 2Iron clinker: The residue remaining during the processing of electric arc furnace dust after recovering zinc. The residue able to be sold is called “iron contained pellets,” and the residue to be disposed of is called “iron clinker.”