Contributions to a Circular Economy

Battery Recycling

As automobiles undergo what is expected to be a rapid and long-term shift to electric drive and battery capacity becomes increasingly higher, demand is growing for the copper, nickel, cobalt, and lithium used in lithium-ion secondary batteries (LIBs) for electric vehicles, leading to calls for effective resource recycling.

Since 2017, SMM has been recovering and reusing the copper and nickel contained in LIBs through a process that combines the pyrometallurgical copper smelting processes of the Toyo Smelter & Refinery and the hydrometallurgical refining processes of the Niihama Nickel Refinery.

The recovered nickel is processed into a secondary battery cathode active material at the Isoura Plant, which has allowed us to realize Japan’s first “battery to battery” horizontal recycling using materials recovered from used LIBs. SMM’s LIB recycling process facilitates enables efficient processing of used LIBs with high impurity content by using our unique technologies that combining pyrometallurgical smelting and hydrometallurgical refining.

In 2022, through joint development with Kanto Denka Kogyo Co., Ltd., we established technology that recycles lithium from slag containing lithium into high-purity compounds, successfully developing a new process for horizontal recycling of copper, nickel, cobalt, and lithium.

In March 2024, we decided to construct recycling plants to recover copper, nickel, cobalt, and lithium from used LIBs and other materials on the grounds of the Toyo Smelter & Refinery and the Niihama Nickel Refinery. Construction of the plants is scheduled to start in FY2024 and be completed in the middle of 2026. The capability of the facilities at the plants, which means the volume of raw material can be processed, is planned to be the equivalent amount of approximately 10kt of lithium-ion secondary battery cells per year.

Their design takes into account handling the expecting future increase in used LIB and the metal recovery rate and recycled material inclusion rate defined in EU Battery Regulation in force since August 2023. The plants also incorporate the Company’s own technology for suppressing CO2 emissions, and it shall undertake further technology development and optimization with the goal of reducing its carbon footprint. Additionally, in conjunction with the construction of the plants, we have signed partnership agreements with leading recycling companies to establish a supply chain for used LIB recycling. With this as a spur, we shall work together with our partners and accelerate studies on a collection system for used LIB.

We shall continue with our initiatives towards establishing an LIB recycling system and shall contribute to the achievement of a sustainable circular economy.

■ Recycling Flow

- 1Pre-processing: Heat treatment to eliminate toxins, crushing, and selection

Copper Recycling

GRI 301-2

The SMM Group procures copper and precious metal scrap, as well as used printed circuit boards, from the market. We recover valuable and precious metals by processing these procured materials. Among these procured materials, those containing copper are collectively referred to as copper-based secondary raw materials. Copper is recovered by melting these raw materials in smelting furnaces or converters using surplus heat. The total amount of copper recovered is referred to as the copper recycling volume. We are working to improve processes and consider introducing new equipment to achieve an annual recycling volume of 140kt (copper content) by 2030. This corresponds to a recycling rate of 30% relative to the 460kt annual refined copper production target. In fiscal year 2024, the production of electrolytic copper from secondary copper-based raw materials was approximately 104kt, accounting for 23.4% of total production, which represents a significant increase from the previous year (20.2%).

Zinc Recovery from Steelmaking Flue Dust

At Shisaka Smelting Co., Ltd., a Group company, steelmaking flue dust produced by electric arc steelmaking furnaces at steel manufacturers is used as the main raw material for recovering zinc (crude zinc oxide). After the flue dust is reduced and roasted with coke and other materials, the dust containing volatilized zinc is subjected to hydrometallurgical refining and heat drying to remove impurities and recover the zinc.

Looking ahead, as steel manufacturers are expected to shift to electric arc steelmaking to reduce GHG emissions, the amount of steelmaking flue dust generated is anticipated to increase. In response, Shisaka Smelting is working to improve its processes with the aim of recycling 120kt of steelmaking flue dust per year by 2030.

Precious Metal Recovery

We recover and recycle precious metals (gold, silver, platinum, etc.) using E-scrap as raw material. This E-scrap includes waste home appliances and electronic components collected from all over Japan, as well as waste electronic circuit boards generated during manufacturing processes that contain high concentrations of valuable metals such as gold, silver, copper, and palladium.

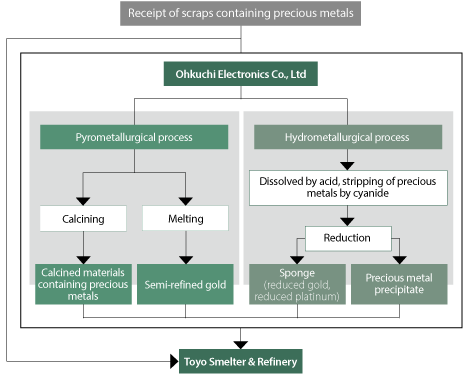

The collected raw materials are sorted at our affiliated company, Ohkuchi Electronics Co., Ltd., into parts containing precious metals and parts that do not. Depending on their composition, the materials are concentrated using either dry or wet processes, and then transported to the Toyo Smelter & Refinery. At the Toyo Smelter & Refinery, these concentrated materials are smelted and refined simultaneously with other copper and precious metal raw materials, and are regenerated into high-purity precious metals.

■ Precious Metal Recovery Flow Diagram

Utilization of Slag

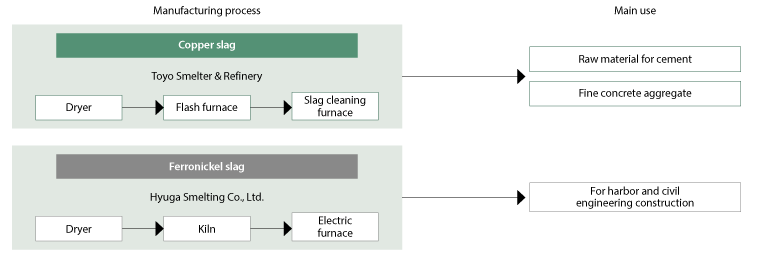

At the Toyo Smelter & Refinery, which is a copper smelter, copper slag is produced as a by-product during the smelting process. The main use for copper slag (80% of the total volume) is cement production for Japan and overseas. With an iron content of about 40%, copper slag is widely used as a source of iron for cement.

The ferronickel slag produced as a by-product at Hyuga Smelting Co., Ltd., which manufactures ferronickel used as a raw material for stainless steel, is mainly used for harbor and civil engineering construction.

Back to Stable Supply of Non-Ferrous Metals and Transition to a Circular Economy